Coating Calculations (The Math) Part 2

A Comprehensive Approach to Coating Calculation for Different Surfaces

Painting Surface Areas

In part one, we looked at the fundamentals of "painting by numbers" on an industrial scale view part 1 of this article for common painting calculations . In part two, we are going to consider these basic formulas applied to more complex structures and will begin with looking at I-beams.

How to Calculate the surface of an I-Beam?

A steel I-beam is essentially broken down to three steel plates that are welded together to create the end result shape. The beams may have stiffeners, although these themselves are also steel plate sections. Therefore, we can use the same formula for length multiplied by width.

An I-beam has top and bottom plates that are positioned horizontally. These are called flanges. The vertical steel plate that connects the top and bottom flanges is called the web.

Stiffeners are also vertical plates that are connected to the top and bottom flanges and the web.

In order to determine the total area of a I-beam for the purpose of coating we simply follow these steps;

- Measure the length and width of one of the flanges and calculate the area by multiplying the length and width found.

- Multiply step 1 by four in order to cover each side of the flange; you may need to deduct the thickness of the flange. This is generally small and not usually calculated unless the thickness is significant.

- Measure the length and width of the web and calculate the area found (L x W).

- Multiply step 3 by x2 (this is doubled due to the web having two faces).

- Finally, measure stiffeners in the same fashion and don't forget to multiply by the number of stiffeners found.

There are various alternative methods of calculation for I-beams however this post is designed to give you an understanding of the basic methodology used.

Coating Calculator

Next we take a closer look at cylinders, or more commonly known as cylinder tanks. These can be calculated if the circumference of one end (typically the roof) can be determined and if the area of the side walls can be calculated.

The side walls of a tank's area are created by simply bending flat steel sheets into the more cylinder shaped curve to create a circle, so the formula to calculate the areas of the side walls is the same formula to calculate the area of the plate.

Coating Cost Calculator

In order to determine the total area of a Cylinder for the purpose of coating we simply follow these steps;

- Obtain the circumference (C) of the tank using the ground or rooftop perimeter (If you're unable to determine either of these, then the circumference can be found using Pi 3.14 multiplied by the diameter (which is determined by the length of a straight line through the centre and touching two points on its edge). For example if the roofs diameter is 15 metres, the circumference (C) is (3.14 x 15) 47.1 meters.

- We then need to calculate the surface area (A) of the vertical sides, which is determined by the circumference (C). If we know the height is 40 meters from the bottom to the top we simply multiply this by the circumference for example (40 x 47.1 = 1,884m2).

The surface area of a pipe can be calculated in much the same way as the method used for cylindrical shapes above, in that knowing the circumference (C) of the pipe along with its length, will provide you with its surface area.

In order to determine the total area of a pipe or pipeline for the purpose of coating we simply follow these steps;

- The circumference is diameter x Pi so for this example we only know the pipe's diameter at 0.5 meters (D 0.5 x Pi 3.14 = C 1.57 meters)

- If determining the surface area of the exterior of the pipe, multiply the length by the circumference, for this example the pipe is 12 linear meters long (12 x 1.57 = 18.84 m2)

- If determining the surface area of the interior of the pipe, possibly to line and pose a reduction in friction or increase fluid flow, although this is generally small and not usually calculated unless the thickness is significant and/or the pipe or pipeline is long, we would use the same formula as described above with the subtraction of pipe wall thickness. For example, the pipe is again 12 meters long with a circumference of 1.57 meters, however the wall thickness is consistent throughout the length at 0.01 meters therefore equal to 18.72 m2

There may be a requirement to estimate the total volume (V) of liquid that a tank or vessel could hold in addition to calculating its surface area for coating purposes.

In order to determine the total volume (V) of a box or storage tank for the purpose of coating we simply follow these steps;

- Calculate the length (L)

- Calculate the Height (H)

- Calculate the Width (W)

- (V = L x H x W)

If the box or tank is 30 meters long and 30 meters height by 20 meters wide (L30 x H30 x W20 = 18,000m3) then 18,000 cubic meters is the volume.

Coating Thickness Formula

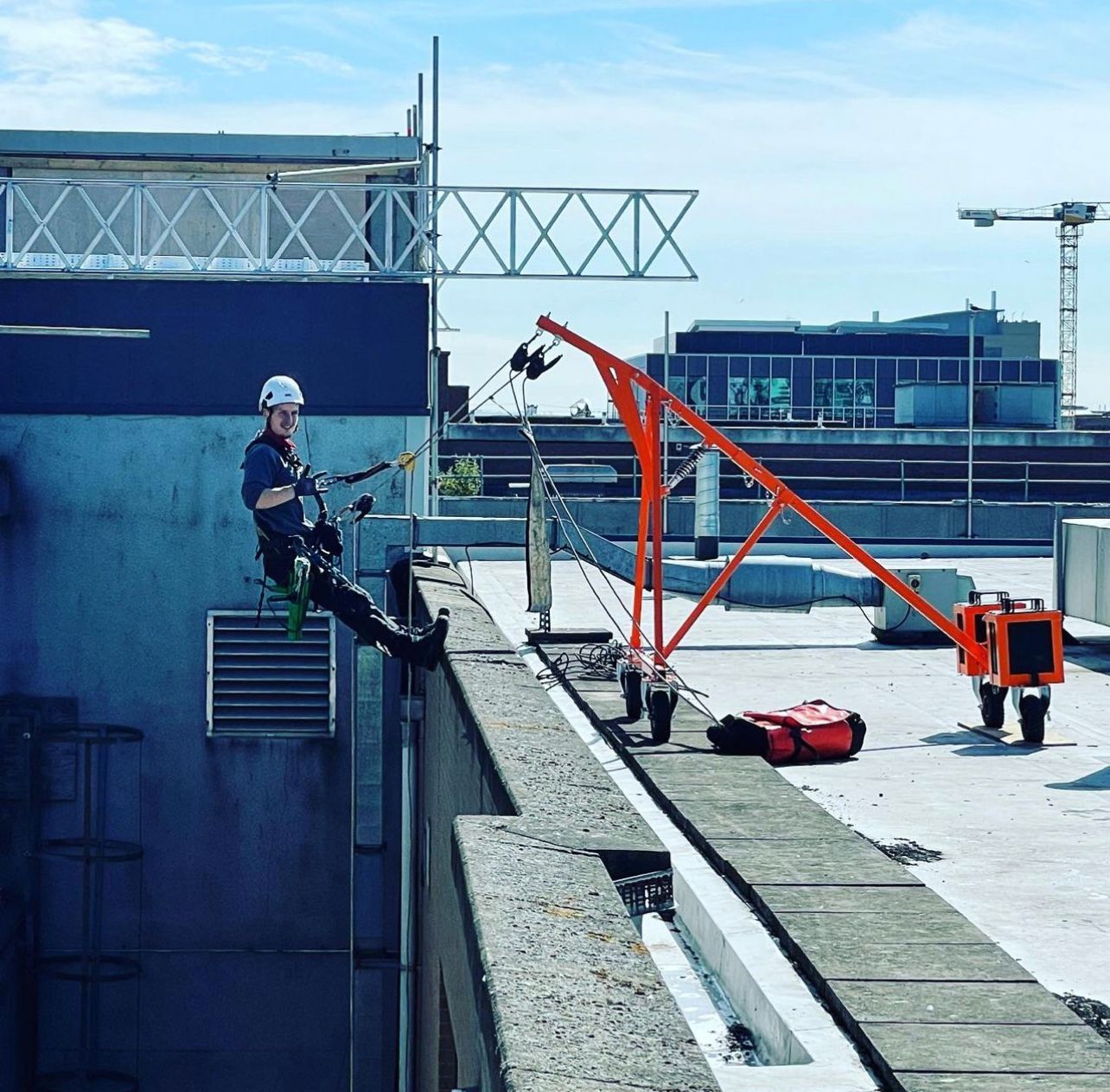

About Dangle Rope Access

Here at Dangle Rope Access, we provide a variety of comprehensive inspection, access, coatings, and composite (IACC) industrial services. Our services are available to both the private and public sectors.

We offer high-quality proven solutions that will help reduce maintenance costs in both the long and short-term. We are based in Dundee, Scotland and also have offices based in Edinburgh, along with our newly established training centre in Northern Ireland Dangle Academy. Due to our company size and structure, we are able to offer a flexible and versatile approach to the way we run our business and the services that we offer our clients. And, as a leading painting company, we’ve worked on several renewable energy projects in the UK, Europe, and the US.

We work with both on and offshore with wind farm operators, and asset owners. For offshore wind farm maintenance, to onshore building maintenance, we can cover both the East and West coasts.

To find out more about how our team can help you contact us today. Our friendly, professional and helpful team is always on hand to help.

Paint Formulation Calculations

We'd love a share...