Scaffolding Alternatives

Scaffolding Alternatives: The Advantages of Rope Access for Your Next Project

When it comes to industrial maintenance, construction, or even intricate inspections, the traditional methods of scaffolding often come with a host of challenges, like high costs, time-consuming setup, safety risks, and the need for large crews. As the demand for efficient, cost-effective, low emissions and innovative solutions rises, scaffolding alternatives are gaining traction in the UK.

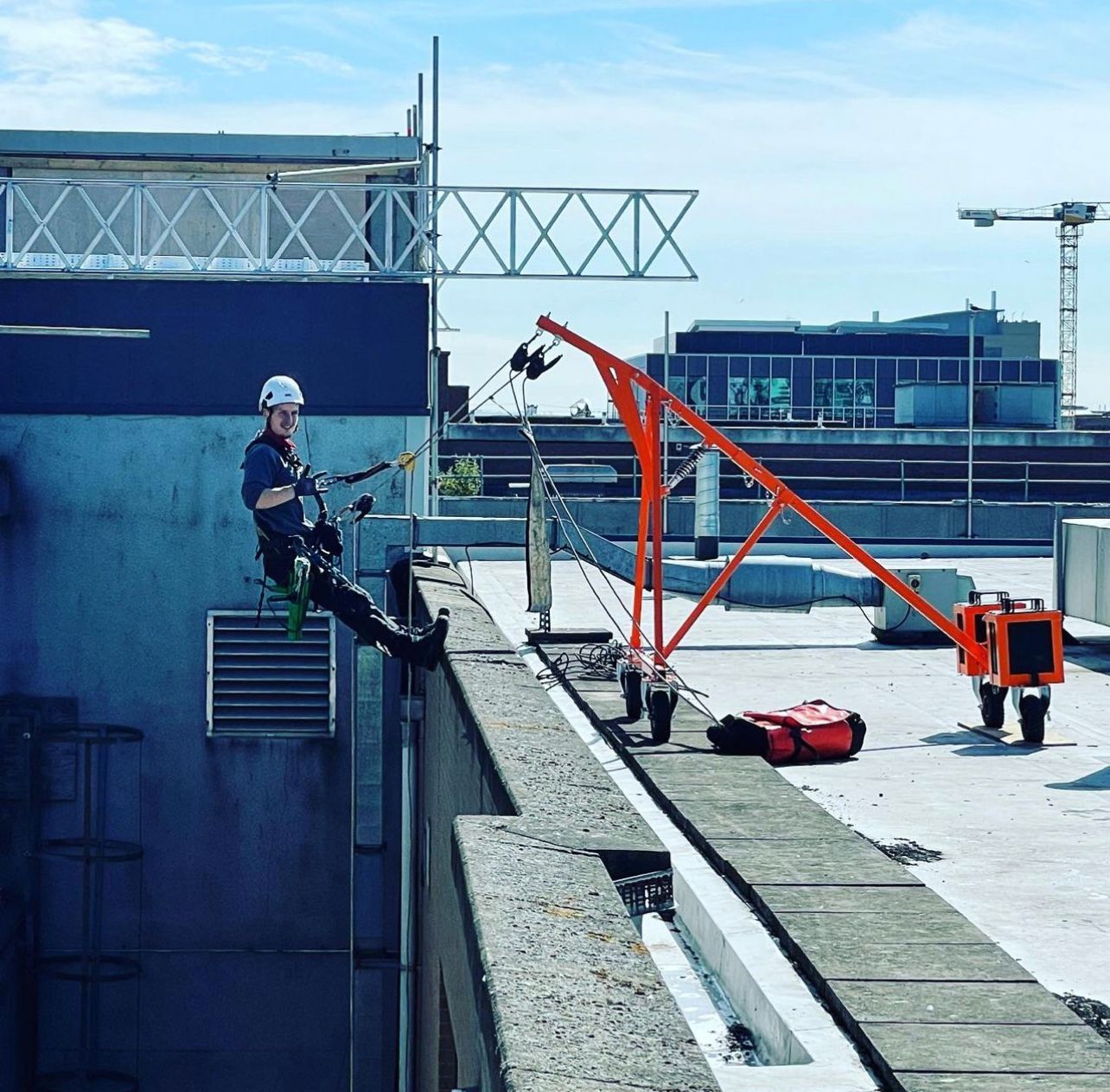

One such alternative that has revolutionised access across a range of industries, is rope access.

In this article, we’ll explore why rope access is becoming one of the most sought-after scaffolding alternatives, especially when it comes to improving safety, saving time, and reducing costs. We’ll also take a closer look at how Dangle, an industry leader in rope access services, can help your business achieve superior results through this innovative solution.

Understanding Rope Access

Rope access is a highly specialised technique that allows professionals to safely ascend, descend, and traverse various structures using ropes, harnesses, and other fall protection equipment. It has been used for decades in industries such as construction, building maintenance, oil and gas, and utilities, and it has proven to be an effective alternative to traditional scaffolding. Read more about the history of rope access and how it evolved from caving in another one of our in depth blog posts, or read on here, about what is rope access.

The technique involves highly trained personnel known as rope access technicians, who are certified by recognised organisations such as IRATA (Industrial Rope Access Trade Association) or SPRAT (Society of Professional Rope Access Technicians). These experts use advanced rope systems to reach difficult or elevated locations, performing tasks like inspections, repairs, and installations with precision.

The Growing Demand for Scaffolding Alternatives

Scaffolding has long been the go-to solution for accessing high or hard-to-reach areas. However, it comes with its own set of limitations:

1. Time-Consuming Setup: Building scaffolding for large or complex projects often requires significant lead time and a considerable workforce of scaffolders.

2. High Costs: Materials, labor, and rental costs can add up quickly, especially for large-scale operations.

3. Safety Concerns: If not constructed or maintained properly, scaffolding can pose a significant risk to workers and the public, and requires regular 7 day inspections.

4. Space Requirements: Scaffolding takes up a large footprint and can limit access to the surrounding environment, making it challenging for projects in densely populated areas.

These limitations are prompting many companies to consider scaffolding alternatives like rope access, which addresses many of the challenges associated with traditional methods, and has a superior safety record.

The Key Benefits of Rope Access

Cost-Effectiveness

One of the most significant advantages of rope access over scaffolding is its cost-effectiveness. Setting up and maintaining scaffolding involves considerable expenses, including material costs, labor, and equipment rentals. Rope access, on the other hand, requires fewer personnel and less equipment, significantly reducing overhead costs.

With rope access, you don’t need to worry about the extensive groundwork, permits, weekly scaffold inspections or scaffolding materials. The equipment required for industrial rope access is compact, lightweight, and can be easily transported to the work site, reducing logistical complexity and set up.

For many businesses, this can translate into significant savings, especially for projects that need frequent or temporary access. By choosing Dangle’s rope access services, you can reduce your overall project costs while still achieving outstanding results, in rapid time.

Speed and Efficiency

Rope access offers unparalleled speed and efficiency, making it an ideal scaffolding alternative for projects with tight deadlines. The setup process for rope access is far quicker than that of traditional scaffolding. While scaffolding may take days or even weeks to be built depending on the size of the structure, rope access teams can typically mobilise and begin work within hours of arriving at the work site.

Moreover, rope access technicians are highly skilled and trained to complete their tasks efficiently and safely, minimising downtime and improving productivity. This speed can help businesses meet deadlines more effectively, keeping projects on schedule and within budget.

For example, Dangle’s rope access technicians can perform a variety of tasks, from window cleaning to conducting building inspections, without the need for lengthy setup times, helping you complete your projects in a fraction of the time it would take using scaffolding.

Safety and Risk Mitigation

Safety is always a priority on any construction or maintenance project. While scaffolding is generally safe when erected properly, it still presents a number of risks. These include structural failure, falling debris, and the possibility of workers being injured during the setup or takedown process, not to mention the need to have extra personnel on the scaffold once constructed to perform the work required.

Rope access offers an added layer of safety by minimising the risks associated with scaffolding. Since rope access doesn’t require large structures to be built, the risks of collapse, instability, and other structural issues are eliminated. Additionally, rope access technicians undergo rigorous safety training for work at height, to ensure they follow the highest standards of fall protection and risk management.

With Dangle, our rope access specialists are fully certified and highly trained in the latest safety protocols for height works. We adhere to strict safety regulations to ensure that every project is completed safely and securely, minimising the likelihood of accidents on the job.

Minimal Disruption and Flexibility

Another major advantage of rope access is the minimal disruption it causes to the surrounding environment. Scaffolding can take up significant space, obstruct pedestrian pathways, or limit access to nearby areas. This can be problematic in dense urban environments, where space is at a premium.

Rope access, on the other hand, is far less intrusive. Technicians can access even the most challenging locations without disrupting the surrounding area. Whether it’s working on the exterior of a high rise building, performing inspections on an offshore oil rigs derrick, or repairing communication towers near busy roads, rope access can be adapted to a wide variety of settings.

Dangle offers flexible and adaptable solutions that are tailored to your unique needs. No matter how complex or unusual your project is, we can provide efficient and non-disruptive access.

Access to Hard-to-Reach Locations

One of the primary benefits of rope access is its ability to provide access to difficult or hard-to-reach locations. Scaffolding is limited by the need for a stable base and space to erect structures, meaning it’s not always suitable for projects in confined or complex environments.

Rope access, however, can reach places that scaffolding simply cannot. This is particularly useful in industries such as oil and gas, telecommunications, and construction, where work is often required in precarious or high-altitude locations, often on uneven, unstable ground or above water.

Rope access can be used to perform inspections, repairs, and maintenance on structures such as bridges, wind turbines, high rise buildings, pylons and pipelines, without the need for cranes or scaffolding towers. This makes it an ideal solution for projects where traditional access methods are impractical or costly.

Why Choose Dangle for Rope Access Services?

At Dangle, we are proud to offer comprehensive rope access services to industries of all types. Here are just a few reasons why we should be your first choice for scaffolding alternatives:

Certified Experts

We employ only certified and experienced rope access technicians who undergo continuous training to stay updated on the latest safety standards and industry practices. Our team is certified by leading organisations such as IRATA, ensuring that we meet or exceed the highest standards of quality and safety for work at height in the industry.

Customised Solutions

Every project is different, and we understand that one-size-fits-all solutions don’t always work. Our team will assess your specific needs and create a tailored rope access plan that ensures efficiency, safety, and cost-effectiveness. Whether it’s a large-scale industrial project or a small maintenance task, we’ve got you covered.

Cutting-Edge Equipment

We use state-of-the-art rope access equipment that is both reliable and safe from world leading manufacturer Petzl. Our equipment is regularly inspected and maintained to ensure it meets safety standards and operates at peak efficiency.

Commitment to Safety

At Dangle, safety is our top priority. Our technicians follow strict safety protocols, conduct thorough dynamic risk assessments before beginning any project, and have daily toolbox talk meetings before the start of work each day. We maintain a zero-tolerance policy for safety breaches, ensuring that every team member is always protected and all involved in working at height activities, return home safely.

Competitive Pricing

By using rope access as an alternative to scaffolding, we can offer our clients significant savings in time and money. Our efficient processes and low overheads allow us to pass those savings on to you, providing high-quality rope access services at competitive rates.

Proven Track Record

With years of experience in the industry, Dangle has successfully completed a wide range of projects across multiple sectors. From high-rise building inspections to offshore oil platform maintenance, our team has the expertise and knowledge to handle even the most challenging projects.

Make the Switch to Rope Access Today

The construction and maintenance industries are evolving, and businesses need to adapt to stay competitive with ever rising costs. Scaffolding alternatives like rope access are no longer just a niche option—they are fast becoming the preferred method for accessing high, difficult-to-reach locations with greater efficiency and safety.

With Dangle, you can take advantage of the many benefits that rope access offers, from reduced costs to faster project completion times, all while ensuring the highest levels of safety and professionalism. If you’re looking for a reliable and cost-effective scaffolding alternative, contact us today to learn more about how we can help you with your next project.

By choosing Dangle, you’re choosing a partner who understands the importance of innovation, efficiency, and safety in every aspect of your project. Let us help you take your business to new heights—literally and figuratively!

Request a Free Consultation with Dangle Rope Access Today

Here at Dangle Rope Access, we provide a variety of comprehensive inspection, access, coatings, and composite (IACC) industrial services. Our services are available to both the private and public sectors.

We offer high-quality proven solutions that will help reduce maintenance costs in both the long and short-term. We are based in Dundee, Scotland and also have offices based in Edinburgh, along with our newly established training centre in Northern Ireland Dangle Academy. Due to our company size and structure, we are able to offer a flexible and versatile approach to the way we run our business and the services that we offer our clients. And, as a leading painting company, we’ve worked on several renewable energy projects in the UK, Europe, and the US.

We work with both on and offshore with wind farm operators, and asset owners. For offshore wind farm maintenance, to onshore building maintenance, we can cover both the East and West coasts.

To find out more about how our team can help you contact us today. Our friendly, professional and helpful team is always on hand to help!