Hiring the Right Painting Company

The Role of Professional Painting Companies

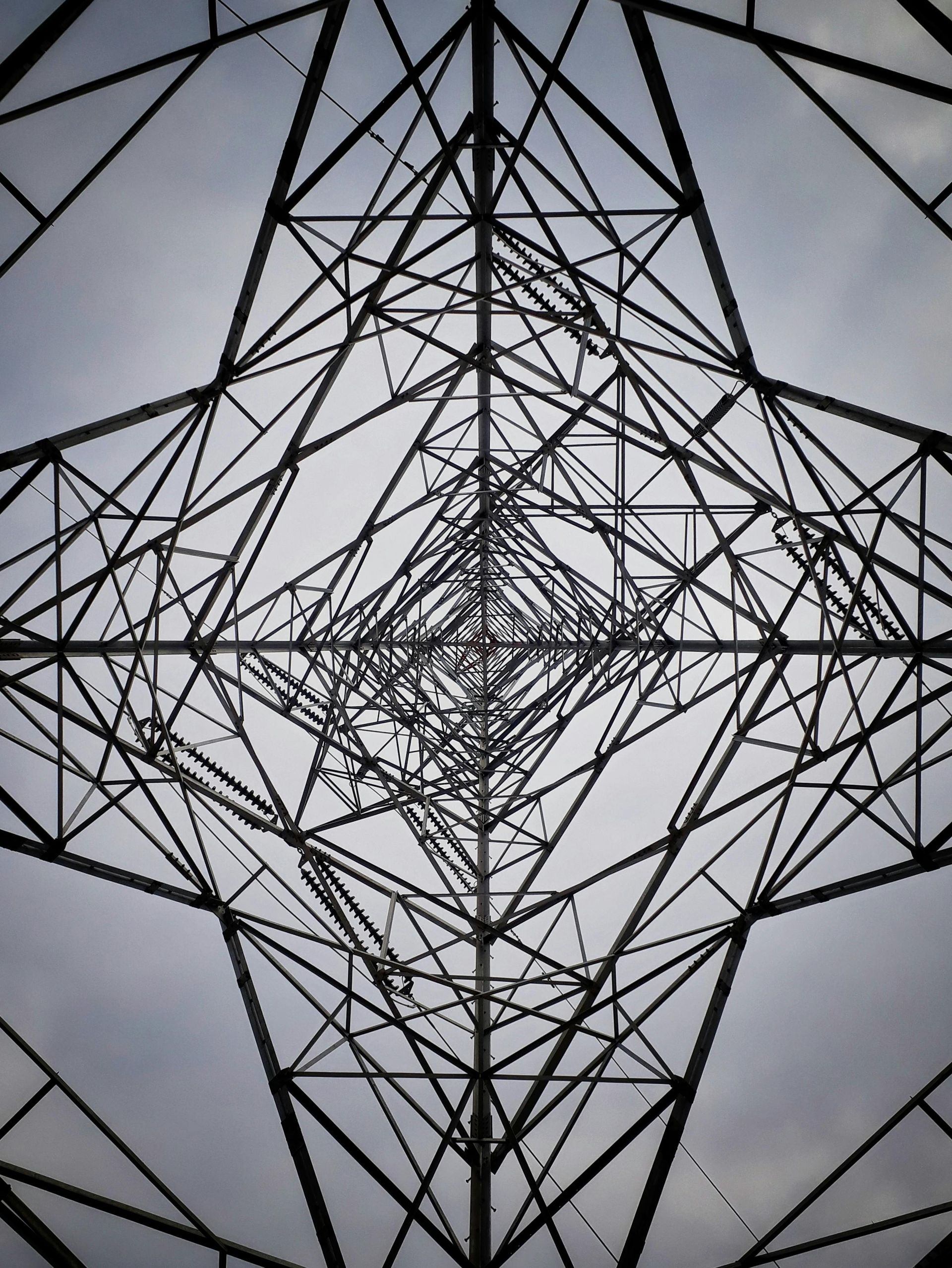

When it comes to maintaining the aesthetic appeal and longevity of a steel structure, the services of professional painting companies cannot be overstated. These skilled paint contractors possess the expertise, equipment, and resources to deliver high-quality painting results that asset owners and managers can rely on.

Exterior painting contractors play a crucial role in preserving the asset life, protecting it from the elements for longer and enhancing its visual appeal. Commercial painting services, Dangle Rope Access specialises in providing commercial painting services tailored for industrial facilities, wind farms, and other structures. Our experienced team offers a wide range of inspection and coatings options, including comprehensive composite solutions, to help private and public sector companies minimise maintenance expenses. With a focus on reducing costs and optimising efficiency, Dangle delivers proven results in the field of industrial painting and access services.

Engaging the services of reputable paint contractors ensures that the job is completed efficiently, with meticulous attention to detail and a keen eye for colour coordination. Professional painting companies also have the necessary safety protocols in place, minimising disruption and ensuring a seamless painting process. Dangle ensure all of the above with its robust policies and procedures, along with taking care of access utilising its rope access, commercial abseiling painting technicians, also eliminating the need for costly scaffolding or noisy and fuel thirsty mobile elevated works platforms (MEWPs) often called cherry pickers.

Ultimately, the investment in professional painting services is a wise decision that can pay dividends in the long run, when selecting the best painting company, maintaining the value and visual appeal of your steel asset while safeguarding it from the ravages of time and weather.

Key Factors to Consider When Selecting a Painting Company

When selecting a painting company to undertake work on your property, there are several key factors that should be carefully considered. Firstly, it is essential to ensure that the painting contractors are licensed and fully insured, providing the necessary protections for both your company and the workers or wider public.

Having an experienced team of painting professionals, like Dangle, is crucial, as their expertise and attention to detail can make all the difference in the final result. We would recommend you look for companies that have a proven track record and can provide a portfolio showcasing their previous painting work.

Additionally, qualifications such as Train the Painter certification can give you confidence in the skills and training of the industrial painters on offer. This industry-recognised accreditation demonstrates a commitment to high standards and best practices.

Finally, do not underestimate the value of customer reviews and references. Speaking with past clients can provide valuable insights into the company's reliability, professionalism, and the quality of their workmanship. This can help you make an informed decision and select a painting company that will deliver the desired results.

Preparing for a Professional Painting Project

When undertaking a professional painting project, it is essential to approach the task with careful planning and preparation. This blog section will guide you through the key steps to ensure a successful and high-quality outcome.

Preparing Steel Surfaces for Painting

Proper surface preparation is crucial for the longevity and appearance of the paint finish. For steel surfaces, this may involve degreasing, descaling, and applying appropriate primers to create a smooth, clean base for the topcoat. Check out ISO 12944 which describes the types of paint and paint system commonly used for corrosion protection of steel structures, for a full comprehensive guide. We have also posted some really helpful content on surface preparation and corrosion control in other blog posts so be sure to check them out too.

Paint Consultation and Selection

Consulting with a professional paint specialist can help you select the most suitable paint products for your project's requirements, and design a paint specification tailored to your project needs. Factors such as the surface type, expected wear and tear, paint thickness and desired aesthetics should be considered when making the paint selection. Check out our recent blog post on Coating Consultancy here

Paint Calculations and Purchasing

Accurately calculating the required paint volume is vital to avoid over or under-purchasing. Our experts at Dangle can provide guidance on paint coverage rates and other Coating Calculations to help you determine the precise amount needed for your project.

Engaging a Professional Painting Contractor

For larger-scale or complex painting projects, it is often advisable to work with a reputable painting contractor, that can take those in their stride. They can ensure the work is carried out to the highest standards, with the appropriate safety protocols in place, and with Dangle you get exactly that. We have worked all over the globe, both on land and at sea, in everything from C1 to C5 corrosion categories so are confident you'll be in safe hands when mobilising us.

By following these preparatory steps, you can set the stage for a professional painting project that delivers long-lasting, high-quality results.

Budgeting for a Painting Job: Comparing Quotes and Avoiding Hidden Costs

When planning a painting project, it is crucial to carefully compare quotes from different service providers and understand the full scope of costs involved. This formal blog section will explore the key factors to consider when budgeting for a painting job, from average hourly rates to potential hidden fees.

One of the primary decisions is whether to opt for an hourly rate or a fixed quote. Hourly rates can provide flexibility, but may be harder to predict the final cost. Fixed quotes offer more budget certainty, though they require a detailed assessment of the work required. Researching the average cost of painting services in the local area, against similar scopes is advisable to ensure quotes are reasonable.

In addition to the base rate, it is important to watch out for any hidden fees that may arise, such as charges for paint material, equipment, or waste disposal. Obtaining a comprehensive breakdown of all costs upfront can help steel asset owners negotiate painting contracts more effectively and avoid unexpected expenses.

By thoroughly comparing quotes, understanding pricing structures, and identifying potential hidden costs, you can make a more informed decision when budgeting for a painting project and ensure you receive high-quality services within your desired financial parameters.

Ensuring a Smooth Painting Experience

When undertaking a painting project, whether for your home or business, it is essential to ensure a seamless and satisfactory experience from start to finish. Key considerations include maintaining a clear project timeline and open communication, delivering a high quality of workmanship, and providing post-project warranties and guarantees.

Effective project management and transparent communication between the client and painting contractor are vital for setting realistic expectations and keeping the project on track. Regular updates on progress and any potential delays or changes to the timeline will help mitigate frustrations and ensure the client's needs are met.

Equally important is the quality of the actual painting work. Skilled, experienced tradespeople utilising premium materials and techniques can make all the difference in achieving a flawless, long-lasting finish. Clients should seek painters who are fully qualified, insured, and committed to excellence.

Finally, post-project support in the form of warranties and guarantees provides valuable peace of mind. Reputable painting contractors will typically offer guarantees on their workmanship, as well as guidance on proper maintenance to preserve the finish. This level of aftercare demonstrates a commitment to customer satisfaction.

By focusing on these key areas, painting projects can be completed to the highest standard, leaving clients delighted with the final result.

The decision to invest in a professional painting contractor is a wise one that can provide numerous benefits.

Skilled painters possess the expertise, tools, and experience necessary to deliver high-quality results, ensuring a seamless and efficient painting process. Furthermore, professional contractors often offer warranties and guarantees, providing added peace of mind and protection for your investment.

When selecting a painting company, it is crucial to thoroughly vet their credentials, reviews, and pricing to ensure you are making an informed decision that aligns with your specific needs and budget.

About Dangle Rope Access

Here at Dangle Rope Access, we provide a variety of comprehensive inspection, access, coatings, and composite (IACC) industrial services. Our services are available to both the private and public sectors.

We offer high-quality proven solutions that will help reduce maintenance costs in both the long and short-term. We are based in Dundee, Scotland and also have offices based in Edinburgh, along with our newly established training centre in Northern Ireland Dangle Academy. Due to our company size and structure, we are able to offer a flexible and versatile approach to the way we run our business and the services that we offer our clients. And, as a leading painting company, we’ve worked on several renewable energy projects in the UK, Europe, and the US.

We work with both on and offshore with wind farm operators, and asset owners. For offshore wind farm maintenance, to onshore building maintenance, we can cover both the East and West coasts.

To find out more about how our team can help you contact us today. Our friendly, professional and helpful team is always on hand to help!