Rope Access Services

Top Rope Access Services You Didn't Know About

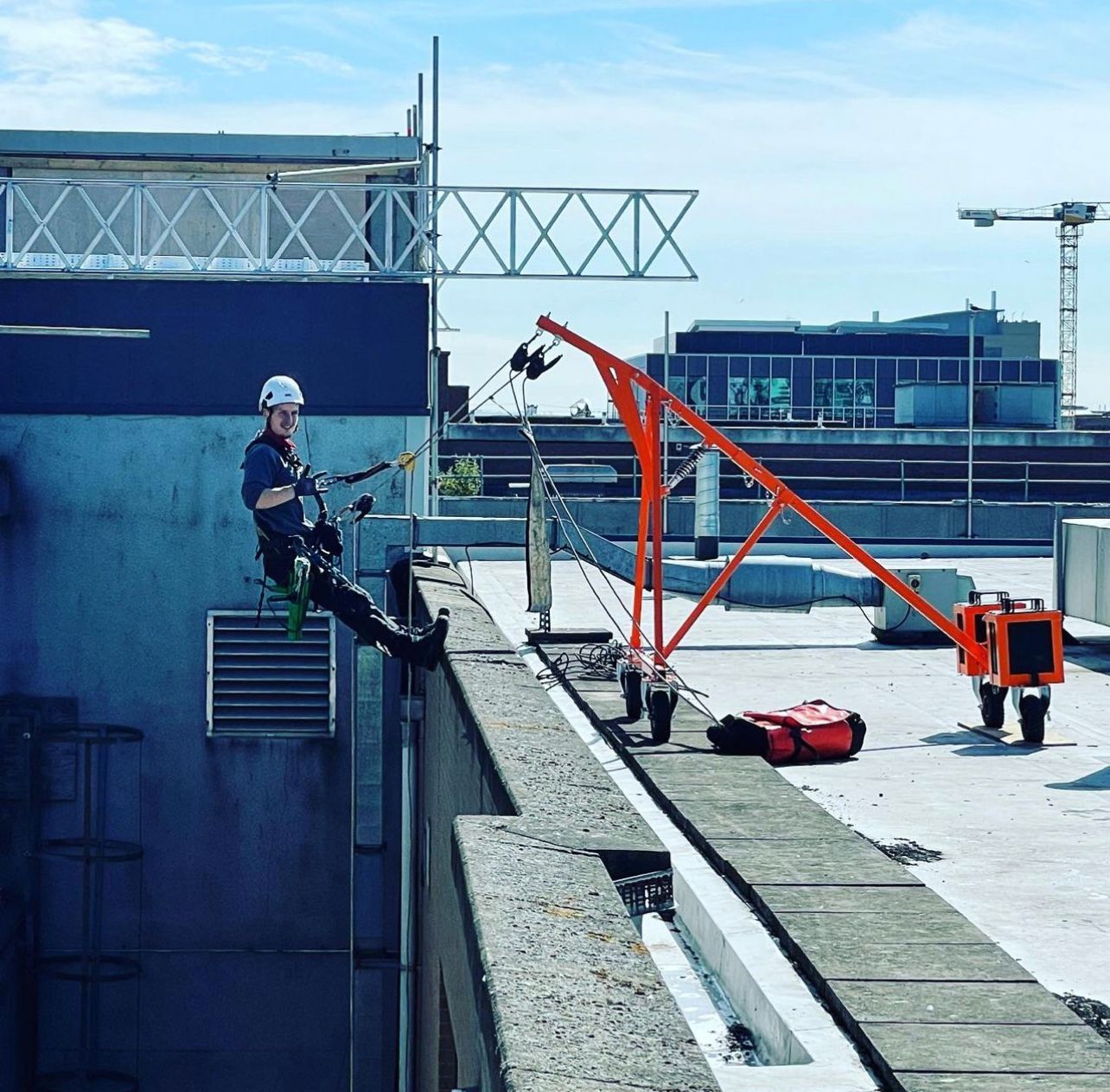

When most people hear the term rope access services, they often picture high-rise window cleaners or oil rig maintenance workers suspended dozens of metres above ground. While those are certainly key applications, the capabilities of rope access services extend far beyond these traditional images. In fact, rope access has become a vital solution across a wide range of industries, enabling safe, cost-effective, and versatile work in challenging environments.

In this article, we dive into some of the lesser-known but highly impactful uses of rope access services, and how Dangle—one of the UK's leading providers—is delivering these services across the country and worldwide.

Wind Turbine Blade Inspection and Repair

The global shift toward renewable energy has created enormous demand for wind power, and with it, a growing need for ongoing maintenance of wind turbines. These tall structures, often in remote or offshore locations, pose unique challenges for access and inspection. This is where rope access services truly shine.

Rope Access Key Benefits:

- Access to Difficult Locations: Rope access enables technicians to reach blade tips and nacelles with ease, avoiding the need for costly cranes or mobile platforms.

- Operational Efficiency: Minimal setup time and reduced downtime mean wind farms stay productive.

- Cost-Effective Maintenance: Eliminates reliance on heavy equipment, making repairs and inspections significantly more affordable.

Rope Access Industry Insight:

According to the Global Wind Energy Council (GWEC), global wind energy capacity reached an impressive 743 gigawatts (GW) by the end of 2023, marking a significant milestone in the transition towards cleaner, more sustainable energy sources. Europe remains a key player in this movement, accounting for approximately 40% of the total installed capacity, with countries like the UK, Germany, and Denmark leading the charge in both onshore and offshore wind development. As the scale and complexity of wind farms continue to grow, so too does the need for effective and efficient wind turbine maintenance solutions—particularly for turbine blades, which are prone to wear and damage from weather, erosion, and operational stress. In response to this demand, rope access services have emerged as the preferred method for many wind energy providers.

Bridge Maintenance and Inspection

Bridges are critical infrastructure, and their upkeep is essential for public safety. However, many parts of a bridge—such as undersides, support columns, or archways—are extremely difficult to access using traditional means. Rope access services provide a safer and more flexible solution.

Rope Access Key Benefits:

- Non-Intrusive Setup: No need for large equipment or road closures in most cases.

- Enhanced Safety: Rope access technicians are certified to IRATA standards and trained to work in high-risk environments.

- Precise Access: Ideal for reaching areas like soffits, piers, and cable anchorages.

Rope Access Industry Insight:

Over the past decade, the UK government has invested more than £15 billion into the upkeep and modernisation of national bridge infrastructure. This significant funding has supported the inspection, repair, and strengthening of thousands of bridges across the country, from rural crossings to major urban transport links. As the infrastructure network ages and demands on it increase, ensuring the integrity and safety of these structures has become more critical than ever. A substantial portion of this investment now incorporates rope access services, which have proven to be an invaluable tool for engineers and maintenance teams. Particularly on complex and difficult-to-reach structures—such as suspension bridges, cantilever spans, and arch bridges—rope access enables highly trained technicians to carry out detailed inspections, non-destructive testing, structural repairs, and corrosion protection without the need for disruptive scaffolding or costly under-bridge units.

Telecommunications Tower Maintenance

Modern communication relies heavily on a vast network of towers, antennas, and masts. These structures must be regularly maintained to ensure consistent signal strength and data transmission. For this, rope access services offer unmatched speed, safety, and adaptability.

Rope Access Key Benefits:

- Fast Deployment: Ideal for urgent repairs or rapid upgrades.

- Minimal Disruption: Work can be completed without interrupting service or requiring shutdowns.

- Low Cost: Avoids the use of helicopters or large lift machinery.

Rope Access Industry Insight:

With mobile device usage continuing to rise globally—surpassing 8.9 billion subscriptions in 2023—the demand for tower inspections and upgrades has never been higher. This exponential growth in mobile and data consumption has placed unprecedented pressure on telecommunication providers to expand network coverage, upgrade equipment, and maintain the structural integrity of towers and masts. Ensuring uninterrupted service requires frequent inspections, routine maintenance, and the swift deployment of new technology, such as 5G transmitters and antenna arrays. In response, rope access services have become a go-to method for telecom companies seeking a rapid, cost-effective, and low-impact solution.

Confined Space Entry for Industrial Inspections

From chemical plants to power stations, industrial facilities are full of confined spaces—tanks, boilers, silos, pipelines—that are difficult and dangerous to access. Rope access services enable trained professionals to enter and work safely in these environments.

Rope Access Key Benefits:

- Superior Safety: Rope access practitioners follow strict safety protocols for entry, ventilation, and emergency rescue.

- Operational Continuity: No need to dismantle equipment or shut down processes entirely.

- Versatility: Ideal for internal inspections, cleaning, and minor repairs.

Rope Access Industry Insight:

The UK’s Health and Safety Executive (HSE) reported 27 fatalities between 2011 and 2021 due to accidents in confined spaces. With the use of rope access, safety records improve significantly due to comprehensive risk management and emergency planning. This proactive approach to safety not only reduces the likelihood of accidents but also enhances the overall efficiency of confined space work by allowing teams to complete their tasks quickly and effectively, without compromising on safety.

Heritage Building Restoration

Preserving historic buildings presents a delicate challenge: maintain their structural integrity without damaging their architectural heritage. Rope access services offer a gentle, precise method of restoration and maintenance, without the intrusive scaffolding that can mar or even harm delicate façades.

Rope Access Key Benefits:

- Preservation-First Approach: No drilling or anchoring that could damage stonework or detail.

- Visual Clarity: Allows full visibility of the structure during restoration.

- Discreet Operations: Perfect for listed properties in residential or urban areas.

Rope Access Industry Insight:

Historic England—the public body tasked with safeguarding England's historic environment—has allocated over £100 million towards the preservation and restoration of heritage buildings over the past few years. This funding is part of an ongoing effort to protect the UK's rich cultural heritage, which includes some of the world's most iconic and architecturally significant structures. Today, rope access services have become the preferred solution among conservationists, architects, and heritage building specialists for projects that require both precision and sensitivity. Rope access allows skilled rope access technicians to reach otherwise difficult-to-access areas such as high walls, ornate roofs, and intricate stonework without the need for intrusive scaffolding or cranes, which can sometimes obscure or damage the building's historical features.Whether it’s repairing weathered stone facades, restoring historic ironwork, or cleaning stained-glass windows, rope access offers an efficient, flexible, and cost-effective way to preserve the beauty and heritage of these cherished buildings, all while minimising disruption to the surrounding environment.

Underwater Inspections and Maintenance

When we think of inspections and repairs, we often forget what lies below the waterline. Rope access services are now being integrated with commercial diving operations to facilitate underwater inspections and repairs on structures like harbour walls, wind turbine foundations, bridge piers, and offshore platforms.

Rope Access Key Benefits:

- Surface-to-Subsea Integration: Rope access divers can seamlessly transition from topside rigs into the water.

- Safety-First Execution: Operates within Industrial Rope Access Trade Association (IRATA) and International Marine Contractors Association (IMCA) standards for dual-safety compliance.

- Cost and Time Savings: Reduces the need for remotely operated vehicles (ROVs), barges, and elaborate dive spreads.

Rope Access Industry Insight:

According to the Subsea UK Business Activity Review, the demand for underwater inspection services has surged by an impressive 18% since 2020, reflecting the increasing need for accurate, efficient, and cost-effective solutions in the subsea and marine industries. This growth is driven by several factors, including the expansion of offshore energy projects—such as oil and gas rigs, offshore wind farms, and tidal energy generators—as well as the ageing infrastructure of coastal and port facilities. As the complexity and scope of these projects increase, so does the need for detailed inspections and ongoing maintenance of submerged assets. One of the most significant advancements in the field has been the rise of integrated rope access and diving teams. This integrated approach has become the new standard for marine infrastructure projects, particularly in tidal zones and remote offshore locations, where access can be challenging, and downtime must be minimised.

Learn More About Dangle Rope Access Today

Here at Dangle, we provide a variety of comprehensive inspection, access, coatings, and composite (IACC) industrial services. Our services are available to both the private and public sectors.

We offer high-quality proven solutions that will help reduce maintenance costs in both the long and short-term. We are based in Dundee, Scotland and also have offices based in Edinburgh, along with our newly established training centre in Northern Ireland, Dangle Academy. Due to our company size and structure, we are able to offer a flexible and versatile approach to the way we run our business and the services that we offer our clients. And, as a leading painting company, we’ve worked on several renewable energy projects in the UK, Europe, and the US.

To find out more about how our team can help you contact us today. Our friendly, professional and helpful team is always on hand to help!

We'd love a share...