Coating Consultants

Coating Consultancy

Industrial Painting

The role of a Coating Consultancy – everything you need to know

Coatings not only play a vital role in protecting wind turbines, oil rigs, offshore platforms, buildings and other assets from deteriorating over time, (a law in physics known as thermodynamics) but they also help to maintain the aesthetic appeal of exteriors too. Although less safety critical, still play an extremely important role.

For many structures within a diverse range of sectors, investing in industrial coatings comes hand in hand with major maintenance work. All companies should recognise the importance of investing in a coating consultancy service year after year, to ensure that assets remain in the very best condition, for the longest period of time, with a set maintenance schedule or plan.

But what is the role of a coating consultancy?

The role of a coating consultant covers a broad range of paint related scopes and every task is unique. When it comes to choosing a coating consultancy, you should ensure that the company you choose is able to provide tailored coating solutions that are fit for purpose and accommodate all your needs.

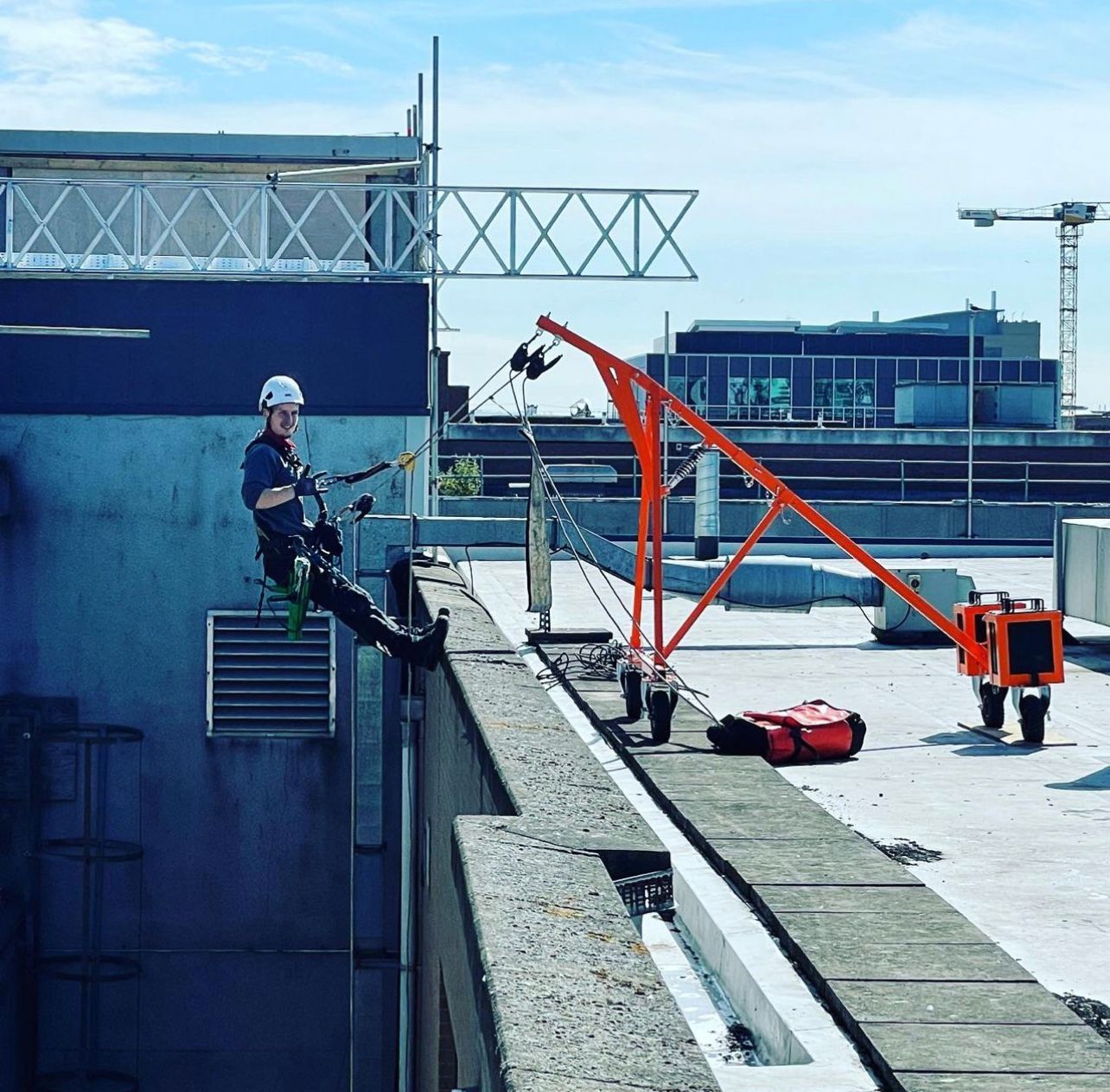

A coating consultancy like Dangle, has Industrial Coating , Paint Inspection & Rope Access Specialists that have a wealth of experience in providing a range of coating inspection services for assets of all shapes and sizes. Proven with the experience, skills and knowledge needed to complete every job we undertake safely, and to the highest standard, Dangle also has access to the latest, state of the art equipment that is designed to handle both small and complex painting jobs right across the globe!

But that’s not all, Dangle also offer a coating consultancy’s role to recognise why paint may have failed which can become noticeable through blistering, loss of adhesion or similar, unexpected and premature deterioration. Understanding the causes is key to avoiding the same, costly faults in future.

Here at Dangle, from the moment you get in touch, we listen carefully to your bespoke requirements in order to provide the latest coatings that maximise longevity, improve performance and of course, meet all the regulatory and industry standards you would expect from world leading coating experts. We believe we are the best in our field and pride ourselves on delivering the highest standard of service, no matter what your painting issue may be or where in the world your asset is located, we can help.

Why are coating inspections important?

Trying to keep metals in the best condition in corrosive environments has always been a challenge, since our ancestors first began making alloys. We have moved on from bringing iron swords in from the rain, however, the problem with corrosion remains and is one that many companies still have to face today. After all, everyday elements such as rain, hail, sea salt, snow, ice and other corrosive elements can cause rusting and structures to deteriorate if they are not protected in the correct way.

The good news is that Dangle are well placed in understanding that there are lots of coating solutions that have been designed to keep buildings, wind turbines, oil rigs, offshore platforms and structures in the very best condition.

How? The application of coating systems are used both onshore and offshore, and involve coating a surface in areas where paint has not been correctly applied, or has suffered from a form of mechanical damage, resulting in exposure of the metallic substrate to the local environment.

Coating systems continually get designed and updated to optimise longevity and performance against corrosion, helping to maximise its service life without the need for expensive structural repair.

Here at Dangle, our expert coating consultancy specialises in providing a world class coating service that has been designed to accommodate all of your bespoke coating needs, in a wealth of different environments, and with ease of access to provide you with the most reliable solutions, FAST!

What other services does a coating specialist like Dangle provide?

Paint Failure Analysis

Dangle have a broad remit of industrial painting skills and have a vast range of knowledge and expertise when it comes to meeting the needs of paint related tasks of all projects, including carrying out paint failure analysis.

Painting failure is a process of fact finding and elimination then should be considered as a first course of action. This should take into account the type of failure, environmental conditions, any unusual or unexpected variations from normal operating conditions, reviewing records of surface preparation and application conditions to ensure they conform to the accepted range for the coating system applied. The information obtained will largely depend on the type of coating failure and at what stage it occurred in the protective coating lifecycle.

Paint Specification Writing

Before a paint project begins, a key task involved in the process is writing the painting work specifications and this involves creating a professional legal document that clearly lays out the materials and processes for the job. They include the types of paints and coatings to be used, and how surfaces should be prepared. Plus the environmental conditions to be observed (think temperature and humidity, for example). They’ll also cover the maximum time interval between surface preparation and priming, as well as between coats. There’s also the number and thickness of coats - the list goes on.

After all, coatings and paints provide long-term protection for a structure and it’s really important that the process is taken extremely seriously.

Why choose Dangle for all of your coating needs?

Dangle's expert team of coating and paint consultants hold advanced, industry-recognised qualifications that allow them to deliver a coating service that fulfils all of our client’s expectations anywhere in the world.

The National Association of Corrosion Engineers (NACE) sets the benchmarks in industrial coatings and their training programmes are recognised in all corners of the globe. We’re also members of the Institute of Corrosion (ICORR). Level 3 qualifications from both organisations guarantee a high level of expertise and Charted status.

With this in mind, you can always rest assured that you are in safe hands when you choose Dangle for your next coating project!

About Dangle Rope Access

Here at Dangle Rope Access, we provide a variety of comprehensive inspection, access, coatings, and composite (IACC) industrial services. Our services are available to both the private and public sectors.

We offer high-quality proven solutions that will help reduce maintenance costs in both the long and short-term. We are based in Dundee, Scotland and also have offices based in Edinburgh, along with our newly established training centre in Northern Ireland Dangle Academy. Due to our company size and structure, we are able to offer a flexible and versatile approach to the way we run our business and the services that we offer our clients. And, as a leading painting company, we’ve worked on several renewable energy projects in the UK, Europe, and the US.

We work with both on and offshore with wind farm operators, and asset owners. For offshore wind farm maintenance, to onshore building maintenance, we can cover both the East and West coasts.

To find out more about how our team can help you contact us today. Our friendly, professional and helpful team is always on hand to help.

Paint Failure

Paint Specifications

We'd love a share...