Wind Turbine Protection

Wind Turbine Protection

Leading Edge Protection

The Advantages of Wind Turbine Protection

It’s not uncommon for wind turbines to succumb to everyday wear and tear.

After all, wind farms are exposed to the harshest elements on land and at sea. Erosion is caused by a number of different factors which are completely outside of our control, and affect different materials in different ways. Erosion and corrosion can be summarised as how materials react with the environment in which they are placed with catalysts including ice, sand, salt spray, insects and rain. And failure to invest in wind turbine protection may lead to a reduced lifespan, with damages to unprotected blades now being reported in as little as two to five years.

Of course, wind turbines are getting larger as they harness more wind energy, which means wind turbine blade erosion is becoming more of an issue for many wind farm owners and/or operators, which is why we have worked tirelessly to ensure that our erosion and corrosion solutions mean we stay up-to-date with the latest high-quality coatings, tapes and soft shells from the world’s leading manufactures like AkzoNobel, Belzona and 3M to name a few.

With this in mind, the good news is that there are now many solutions on offer when it comes to extending the longevity of wind turbine blades, helping them to last longer and perform better. Dangle are not tied down to any sole solutions so we can offer you a whole of market range.

But what is wind turbine protection?

As a general rule of thumb across the industry, the standard wind turbine may last 15 years or more. However, the longevity of a wind turbine is mainly down to the type of elements it is exposed to on a daily basis and how often maintenance intervals are upheld.

For example, salt spray and rain can cause severe erosion and even flying insects and birds can cause a significant amount of costly damage over time, which is why effective wind turbine protection should be prioritised and leading edge protection should almost certainly be your first action point.

How will you know if a wind turbine is damaged?

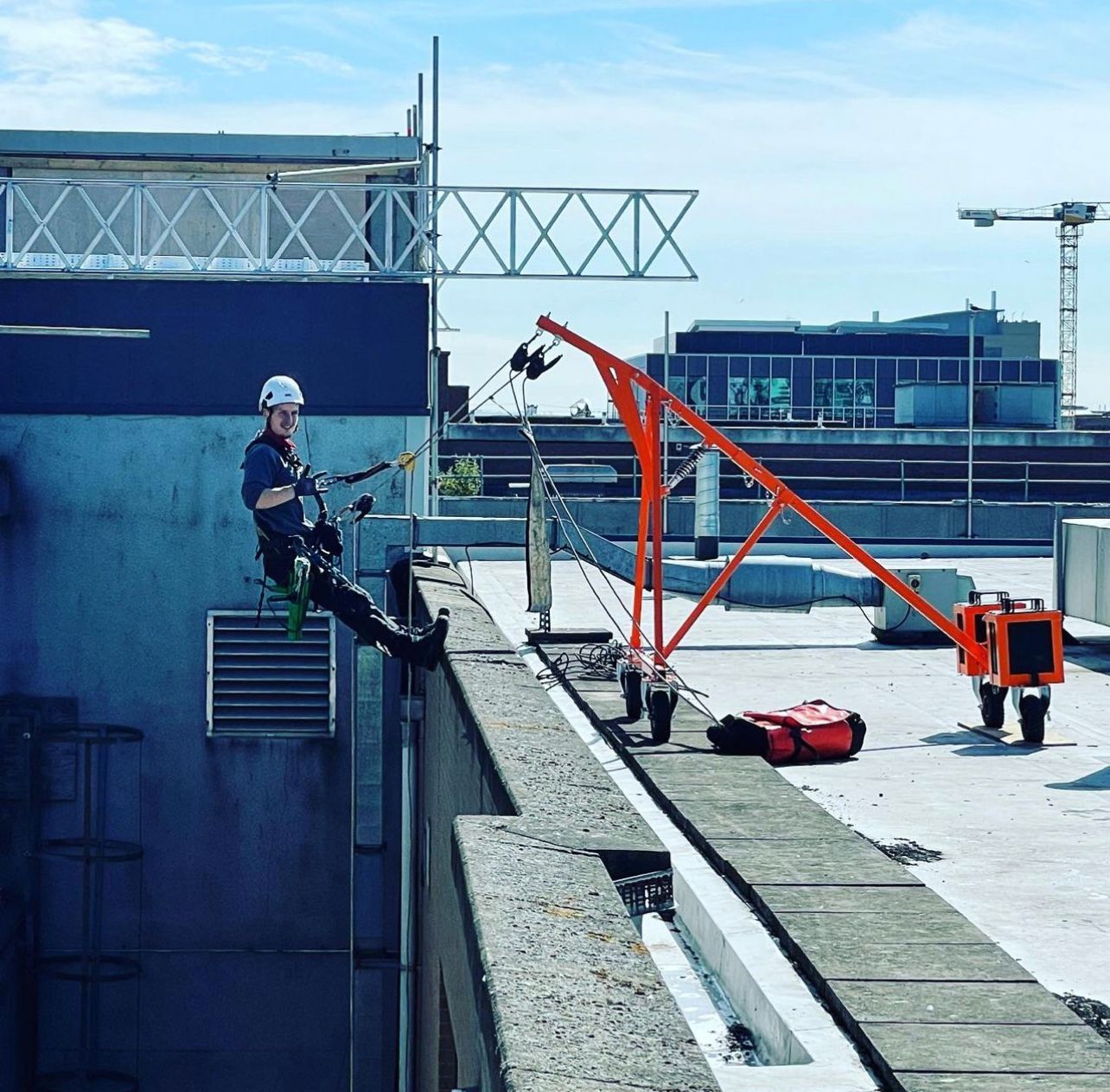

At Dangle our highly trained drone flight pilots and rope access technicians will be able to access the condition of a wind turbine tower, nacelle and blades externally and report back any damage, under a close visual inspection. A rope access technician is responsible for a whole host of maintenance jobs including rust removal, blade repair work and painting as well as inspection tasks which include quality control, safety inspection and coating surveys.

A clear sign that a wind turbine is damaged includes erosion indicators, signs or pitting and the general performance decrease of the wind turbine. This is because signs of pitting can actually affect the turbine speed, causing it to slow down and you’ll also often notice an acoustic change in the sound of each rotation if stood close by.

A reduction in speed of a wind turbine is the last thing energy companies want to deal with as slower turbines mean less energy production and less return on investment.

What preventative measures can you take?

There are lots of preventative steps that you can take to ensure that your wind turbines remain in the best possible condition, including investing in leading edge protection , blade retro fits that improve airflow and reduce drag, carrying out regular inspections and of course, keeping on top of wind turbine maintenance. All of these factors are key when it comes to extending the longevity of your wind turbines.

After all, across all aspects of the industry, avoiding major damage and the costs associated with significant damage should be a top priority. Unprotected wind turbines, or those that have been left to their own device with few inspections, can result in

catastrophic failures as we have seen in the past. Erosion also causes a reduction in aerodynamic efficiency and a loss in operating performance, meaning wind turbine protection is certainly a sound investment.

Why chose Dangle to help with your wind turbine protection needs?

Here at Dangle, we have been providing asset integrity services to the energy sector for several years and are now leaders in our field of work when it comes to providing wind turbine protection solutions that will enhance your day to day business operations.

We have worked on projects in the UK, US and Europe over many years, covering both on-shore and offshore sites and our highly trained and carefully chosen GWO technicians are perfectly equipped with the skills, knowledge and the expertise needed to complete every project to the highest possible standard. We also have extensive experience in industrial access, coatings and composite (IACC) services. This allows us to bring together solutions that maximise your turbine’s output and minimise any downtime. We never compromise on safety, as there’s no margin for error when working at height.

Dangle offers a comprehensive range of wind turbine maintenance services that can be adapted to meet your bespoke needs when it comes to protecting your wind turbines and optimising the longevity of your turbines and their blades.

Leading Edge Protection Coatings

Wind power made up 30% of the UK's electricity generation in the first quarter of 2020, marking a significant milestone in the country's renewable energy journey. As the demand for wind energy continues to grow, it has never been more crucial to invest in reliable and easy-to-apply Leading Edge Protection (LEP) solutions.

At our company, we understand the importance of maintaining optimum blade performance and efficiency in even the harshest and most challenging wind farm environments. That's why we have developed cutting-edge leading-edge protection coatings that are specifically designed to withstand the elements and ensure the longevity of your wind turbines.

Our winter-grade curing agents for two-pack coatings ensure that the protection remains intact even during the harsh winter months when wind turbines are most susceptible to damage. These coatings are formulated to provide superior resistance against extreme weather conditions, including heavy rain, high winds, and freezing temperatures.

In addition to our advanced two-pack coatings, we also offer easy-to-apply one-pack solutions with a lower specific gravity. These solutions are specifically designed to reduce any possible imbalance, ensuring that your wind turbines operate smoothly and efficiently.

When you choose our leading-edge protection coatings, you can rest assured that you are in expert hands. Our team of experienced professionals is dedicated to providing top-notch solutions that not only protect your investment but also contribute to the sustainable growth of the wind energy sector.

Investing in our easy-to-apply Leading Edge Protection (LEP) solutions is not only a smart business decision but also a responsible choice for the environment. By safeguarding the performance and efficiency of your wind turbines, you are actively promoting the use of clean and renewable energy sources, reducing carbon emissions, and contributing to a greener future.

So, don't hesitate to join the growing number of wind energy enthusiasts who trust our leading-edge protection coatings. Contact us today to learn more about our innovative solutions and how they can benefit your wind farm operations. Together, let's harness the power of the wind and pave the way for a sustainable and brighter tomorrow.

Leading Edge Protection Tapes

Thermoplastic polyurethane films are an exceptional solution that offers unparalleled leading-edge protection for wind turbines, effectively safeguarding their efficiency and minimising downtime and maintenance requirements. Moreover, these films play a crucial role in extending the performance lifespan of turbine blades, even in the most extreme and harsh environments.

One of the remarkable aspects of thermoplastic polyurethane films is their effortless application process, particularly when it comes to covering larger sections of the turbines. This ease of application ensures that the films can be conveniently installed, significantly reducing the time and effort required for protection.

By utilising thermoplastic polyurethane films, wind turbine operators can benefit from the utmost level of protection, enabling the turbines to operate at their optimum capacity while minimising the need for frequent maintenance and repairs. These films act as a robust shield against various environmental factors, including extreme weather conditions, UV radiation, and erosion, ensuring that the turbine blades remain in excellent condition for extended periods.

The exceptional properties of thermoplastic polyurethane films make them the go-to choice for wind turbine protection. Their advanced technology and durability provide a cost-effective solution that not only enhances the overall performance of wind turbines but also maximizes their lifespan. With the application of these films, wind energy operators can confidently rely on their turbines to deliver sustainable and efficient power generation, even in the toughest of conditions.

Soft Shell Leading Edge Protection

For blades that are already installed and in-service, a pre-cast soft shell is expertly contoured around the leading edge, positioned approximately 10-15 meters from the tip of the blades (varying based on the size of the blade). This remarkable pre-cast shell seamlessly conforms to the blade's shape, ensuring a flawless fit without any imperfections. Not only does this innovative solution provide enhanced durability, but it also serves as an exceptionally sturdy upgrade for your blades. With this advanced technology, you can rest assured that your blades will receive the utmost protection and performance enhancement.

The pre-cast soft shell, designed specifically for blades that are already installed and in-service, offers an incredible level of protection and performance enhancement. This state-of-the-art solution is meticulously contoured around the leading edge of the blade, expertly positioning it approximately 10-15 meters from the tip (although this distance may vary depending on the blade's size).

The beauty of this remarkable pre-cast shell lies in its flawless fit. It seamlessly conforms to the unique shape of each blade, leaving no room for imperfections. This ensures that your blades are safeguarded with the utmost precision and care, allowing them to function optimally without any hindrances.

But the benefits don't stop there. This innovative technology also provides enhanced durability, making your blades more resilient and long-lasting. No matter the challenges they may face, whether it's harsh weather conditions or rigorous usage, the pre-cast soft shell will act as a shield, protecting your blades from any potential damage.

Moreover, this solution serves as an exceptionally sturdy upgrade for your blades. By incorporating this advanced technology, you are taking a proactive step towards improving their performance. The pre-cast soft shell acts as an extra layer of strength, allowing your blades to withstand greater forces and operate at their peak efficiency.

With this cutting-edge solution, you can have peace of mind knowing that your blades are receiving the ultimate protection and performance enhancement. No matter the task at hand, whether it's powering wind turbines or propelling aircraft, your blades will be equipped with the advanced technology they need to excel. So, why settle for anything less when you can have the best? Choose the pre-cast soft shell and take your blade performance to new heights.

About Dangle Rope Access

Here at Dangle Rope Access, we provide a variety of comprehensive inspection, access, coatings, and composite (IACC) industrial services. Our services are available to both the private and public sectors.

We offer high-quality proven solutions that will help reduce maintenance costs in both the long and short-term. We are based in Dundee, Scotland and also have offices based in Edinburgh, along with our newly established training centre in Northern Ireland Dangle Academy. Due to our company size and structure, we are able to offer a flexible and versatile approach to the way we run our business and the services that we offer our clients. And, as a leading painting company, we’ve worked on several renewable energy projects in the UK, Europe, and the US.

We work with both on and offshore with wind farm operators, and asset owners. For offshore wind farm maintenance, to onshore building maintenance, we can cover both the East and West coasts.

To find out more about how our team can help you contact us today. Our friendly, professional and helpful team is always on hand to help.

Wind Farm Maintenance

Rope Access Blade Repair

We'd love a share...