Advantages of Using Rope Access for High Rise Building Maintenance

High Rise Building Maintenance

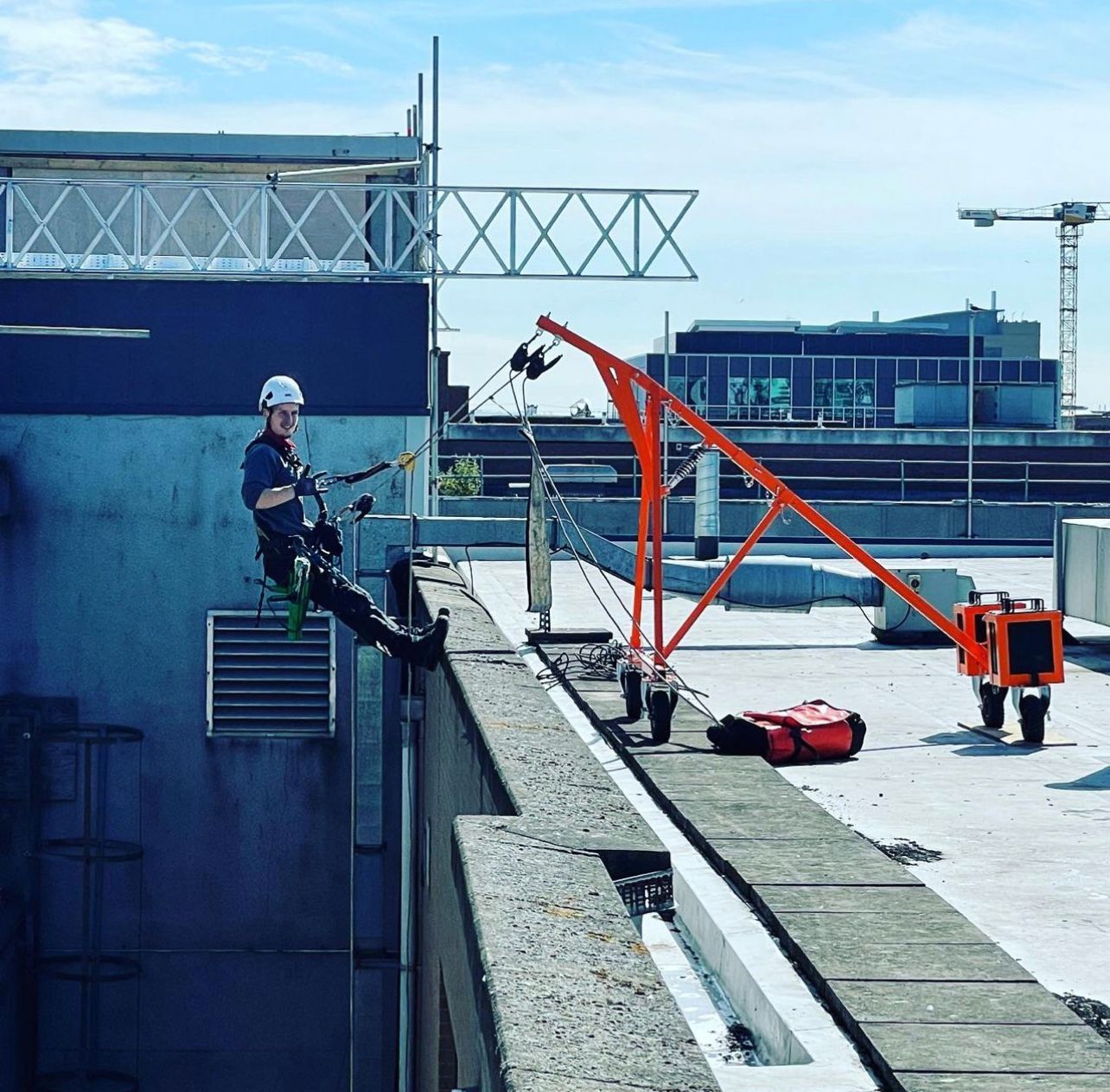

When it comes to high-rise building maintenance, utilising rope access techniques can offer numerous advantages. These include improved safety measures, cost-effectiveness, minimal disruption to building occupants, and the ability to access difficult-to-reach areas with ease.

Rope access provides a flexible and efficient solution for maintenance work on tall structures, allowing Dangle's rope access maintenance teams to carry out tasks with precision and expertise. By employing working at height best practices and essential strategies in high-rise building maintenance, incorporating IRATA rope access/methods can significantly enhance the overall efficiency and effectiveness of the maintenance operations.

Understanding the Importance of High Rise Building Maintenance

High rise building maintenance plays a crucial role in preserving the aesthetics, functionality, and safety of skyscrapers. It encompasses a range of tasks including building exterior cleaning, structural inspections, and general upkeep to ensure the longevity of these iconic structures.

Effective high rise property management involves regular maintenance schedules and adherence to working at height safety regulations to prevent potential hazards. Skilled professionals in this field are essential for maintaining the visual appeal and structural integrity of tall buildings.

By understanding the importance of high rise building maintenance, property owners can ensure that their skyscrapers remain safe, well-maintained, and visually appealing for years to come.

The Key Components of an Effective High Rise Building Maintenance Plan

In the realm of high-rise building maintenance, a comprehensive plan is essential to ensure the longevity and safety of these towering structures. A well-structured high rise maintenance checklist serves as the backbone of such a plan, encompassing crucial aspects such as building facade cleaning, window washing procedures, and stringent safety measures.

Effective maintenance plans for high-rise buildings often include detailed protocols for facade cleaning to uphold aesthetic appeal and structural integrity. Window washing and window cleaning procedures are meticulously outlined to guarantee pristine views while ensuring the safety of maintenance personnel working at heights.

Furthermore, high rise safety measures form an integral part of any maintenance plan, encompassing rigorous protocols to safeguard both occupants and workers against potential hazards inherent in vertical structures. By integrating these key components into a cohesive strategy, high-rise building owners can uphold operational efficiency and regulatory compliance while prioritising occupant safety.

Top Challenges Faced in Maintaining High Rise Buildings and How to Overcome Them

Maintaining high-rise buildings poses unique challenges that require careful consideration and strategic solutions. From skyscraper maintenance challenges to exterior building maintenance difficulties, property managers and facilities teams encounter a range of obstacles in preserving these architectural marvels.

One of the primary challenges faced in maintaining high-rise buildings is ensuring safe and efficient access to all areas of the structure. Weather conditions can also have a significant impact on the exterior of buildings, leading to deterioration and structural issues over time.

To overcome these challenges, implementing innovative high-rise access solutions such as advanced scaffolding systems or robotic cleaning technologies can enhance safety and productivity. Additionally, proactive maintenance strategies tailored to withstand varying weather conditions can help preserve the integrity of the building's exterior surfaces.

By addressing these key challenges with strategic planning and effective solutions, property managers can ensure the longevity and aesthetic appeal of high-rise buildings for years to come.

Sustainability and Green Practices in High Rise Building Maintenance: A Growing Trend

The trend towards sustainability and green practices in high-rise building maintenance is becoming increasingly prevalent. With a focus on eco-friendly skyscraper maintenance, building owners and managers are adopting innovative strategies to uphold green building standards while ensuring efficient upkeep, as we all fast track to net carbon zero targets.

Implementing sustainable high-rise solutions involves the integration of environmentally conscious practices such as rope access, steeplejack services, and roped access services. These methods not only contribute to reducing the environmental impact of maintenance activities, fuel and heavy plant or equipment but also promote energy efficiency and long-term sustainability in high-rise structures.

Elevate Your High Rise Property Management with Proactive Maintenance Approaches

Elevating high-rise property management through proactive maintenance approaches is crucial for ensuring the safety and longevity of buildings. In Scotland, where high-rise maintenance is of paramount importance, utilising innovative techniques such as those adopted by Dangle Rope Access can significantly enhance the efficiency and effectiveness of maintenance operations.

By incorporating Dangle's personnel into high-rise property management strategies, property owners and managers in cities like Dundee, Glasgow and Edinburgh along with other cities in Scotland can access hard-to-reach areas with ease, facilitating thorough inspections and timely repairs.

This proactive approach not only enhances the overall aesthetic appeal of the building but also contributes to cost savings in the long run by addressing maintenance issues before they escalate.

Embracing proactive maintenance approaches in high-rise properties through technologies endorsed by Dangle Rope Access sets a new standard for property management excellence in Scotland, ensuring that buildings are well-maintained and safe for occupants.

About Dangle Rope Access

Here at Dangle Rope Access, we provide a variety of comprehensive inspection, access, coatings, and composite (IACC) industrial services. Our services are available to both the private and public sectors.

We offer high-quality proven solutions that will help reduce maintenance costs in both the long and short-term. We are based in Dundee, Scotland and also have offices based in Edinburgh, along with our newly established training centre in Northern Ireland Dangle Academy. Due to our company size and structure, we are able to offer a flexible and versatile approach to the way we run our business and the services that we offer our clients. And, as a leading painting company, we’ve worked on several renewable energy projects in the UK, Europe, and the US.

We work with both on and offshore with wind farm operators, and asset owners. For offshore wind farm maintenance, to onshore building maintenance, we can cover both the East and West coasts.

To find out more about how our team can help you contact us today. Our friendly, professional and helpful team is always on hand to help!