Rope Access Service Company UK

Rope Access Service Company

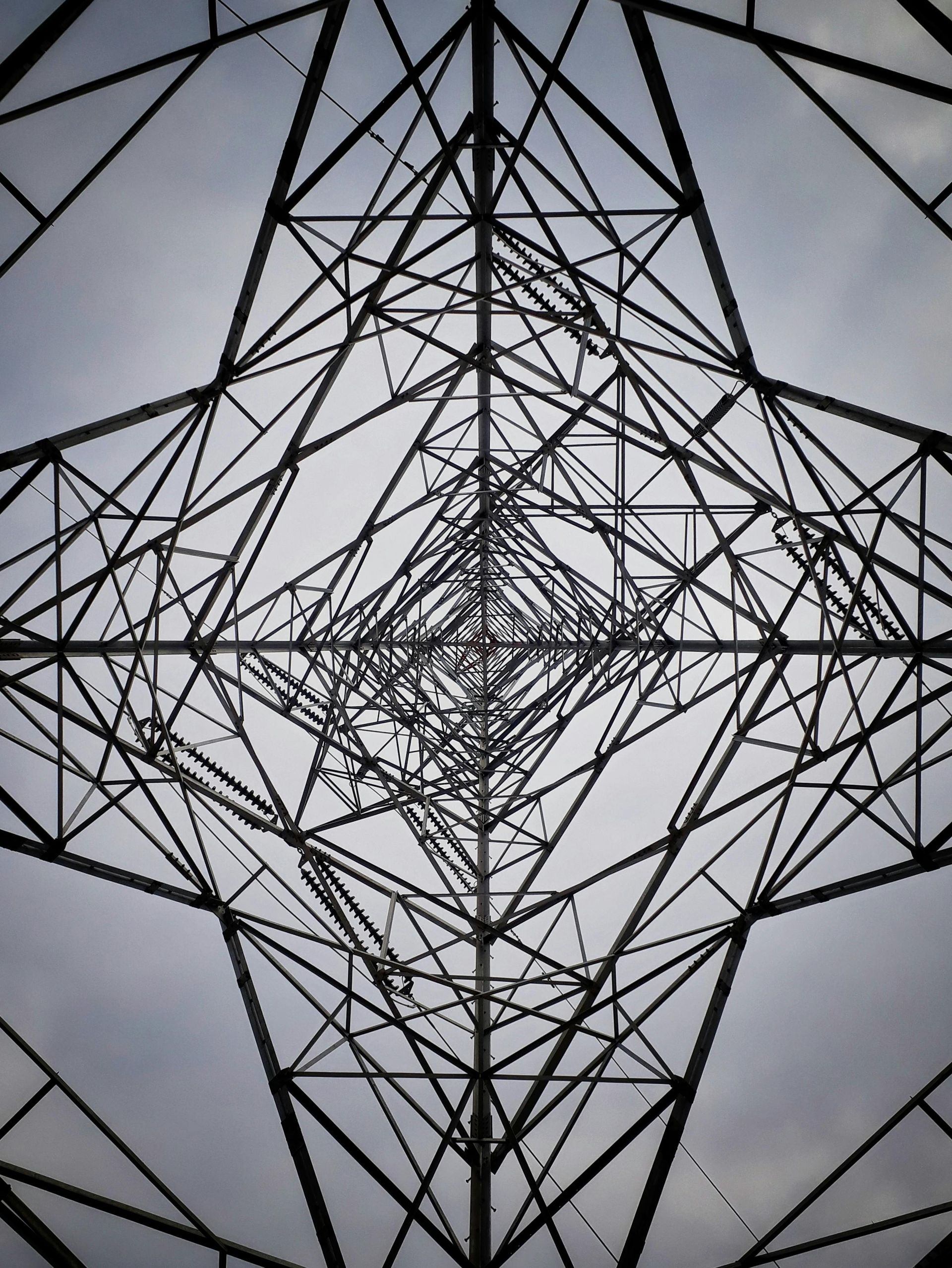

What is Industrial Rope Access?

Rope access is a technique using ropes, normally incorporating two separately secured systems, one as a means of access and the other as back up security, used with a rope access harness in combination with other devices, for getting to and from the place of work and for work positioning. Rope access or industrial climbing is a form of work positioning, initially developed from techniques used in climbing and caving, which applies practical ropework to allow workers to access difficult-to-reach locations without the use of scaffolding, cradles or the use of mobile elevated work platforms (MEWPS).

Many believe that modern industrial rope access techniques were developed from mountaineering and sport climbing disciplines. There is little doubt that many of the original rope access workers came from backgrounds which involved such activities, but the fundamental techniques came from single rope techniques‘ (SRT) developed by cavers.

Instead of using cumbersome ladders to descend and ascend deep shafts, rope techniques were deployed which allowed faster and safer descents and ascents of deep underground systems. Cavers used rope techniques to engineer access and egress to and from such areas.

Rope access technicians descend, ascend, and traverse ropes for access and work while suspended by their harness. Sometimes a work seat may be used. The support of the rope is intended to eliminate the likelihood of a fall altogether, but a back-up fall arrest system is used in case of the unlikely failure of the primary means of support. This redundancy system is usually achieved by using two ropes - a working line and a safety line.

Industrial rope access companies began in the late seventies/early eighties. The deployment of the single rope technique proved to be a safe system with few accidents once it was fully developed. To make it viable for the industrial environment, the system was further developed during the eighties by the addition of a back up security rope thereby providing two levels of redundancy.

Work was carried out on buildings, bridges and other structures such as radar dishes, masts etc. The techniques were readily transferred to the offshore environment. Currently, it is standard procedure to utilise industrial rope access for all manner of inspection, repair and maintenance tasks now offshore in oil and gas and offshore wind energy.

In 1987 the Industrial Rope Access Trade Association was formed (IRATA). This association is now regarded as the lead body for matters relative to industrial rope access both in the UK and worldwide. The UK Health and Safety Executive had significant influence in ensuring that rope access would provide a safe system of working. This resulted in the production of guide-lines which covered the deployment of rope access systems and the certification of personnel involved in industrial rope access by IRATA. The acceptance of industrial rope access as a safe method of working is mirrored in the production of BS 7985: 2013: Code of Practice for the Use of Rope Access for Industrial Purposes. This standard is based upon the original IRATA Guidelines and has formed the basis of the International Code of Practice

(ICOP) which came into effect on the 1st January 2010.

Rope Access Training

Training is a vital element in providing a safe system in any work situation, not just rope access. In the IRATA system, there are three levels of rope technician. The criteria for achieving these levels of competence are detailed in IRATA’s Training and Assessment Certification Scheme, first published in August 2014 (TACS).

To become a IRATA Level 1 requires a minimum four-day intensive training course (minimum of 30 hours) and a one-day assessment carried out by an independent IRATA qualified assessor. The training course includes ascending and descending techniques, knots, equipment appreciation and simple rescue techniques. The training does not include the use of any tools or work skills. A Level 1 (trainee) is defined as a technician who is able to perform a limited range of rope access tasks under the supervision of a level 3.

To achieve IRATA level 2 , the level 1 has to have completed at least 1000 logged hours on rope and have been working in rope access in a wide variety of situations for at least a year. He or she is required to undergo a further 4 days training before this assessment. A level 2 (lead technician) is defined as a technician who is capable of rigging working lines, undertaking rescues and performing other rope access tasks under the supervision of a level 3.

To achieve IRATA level 3 , which is supervisor level, the level 2 has to have at least a further 12 months broad experience in rope access work, with an additional 1000 logged hours on ropes and hold a valid first aid certificate. The candidate then undergoes an independent assessment where competency in advanced rescue techniques and good knowledge of legislation will have to be demonstrated. He or she is required to have a further 4 days training before this assessment. A level 3 rope access supervisor is defined as a technician who is capable of complete responsibility for work projects;

• is able to demonstrate the skills and knowledge required of rope access levels 1 and 2

• is conversant with relevant work techniques and legislation of working at height

• has a comprehensive knowledge of advanced rope access rescue techniques

• holds a current first aid responder certificate

• and has knowledge of the IRATA certification scheme

Training is carried out by specialised IRATA Member training companies. Trainers have to be rope access level 3.

All IRATA certified personnel must be re-assessed every three years.

It is important to understand that rope access training enables successful trainees to gain access or egress to work sites and it is the safe execution of any specific works that is the priority.

What Makes Rope Access Safe?

A risk assessment must be carried out before any activities commence in order that control measures for particular hazards are put in place.

All personnel are responsible both for themselves, their team members and any third parties who may be affected by the activities taking place.

In all circumstances safety will take the highest priority.

When carrying out any rope access (work positioning) manoeuvres, all personnel must be attached to two independent lines, the working rope and backup rope.

All connectors must be fully done up

To work safely at a height requires those engaged in the work to have an appropriate attitude and aptitude for such work.

Those who work at a height need to be confident in exposed places, but not over confident or reckless. Frequently, these workers will work in remote places or will be out of sight of their supervisors. It is, therefore, especially important that the workers can be always relied upon to behave in a sensible, professional and responsible manner.

Rope access work can only be carried out in a safe manner where people are competent, suitably experienced and trained, capable of inspection of their own equipment and subject to appropriate levels of supervision. Because of the potential hazards associated with this work, it is essential that people are properly trained in the use of the methods of access that they will use.

6 x GOLDEN RULES OF ROPE ACCESS SAFETY

- STOP AND THINK

- ALWAYS HAVE 2 INDEPENDENT POINTS OF ATTACHMENT CLOSE CONNECTORS

- KEEP BACKUP DEVICE HIGH

- LOCK OFF DESCENDER

- ALWAYS ADD BEFORE TAKING AWAY POINTS OF ATTACHMENT

- USE THE BUDDY SYSTEM AND NEVER WORK ALONE

Rope Access Risk Assessment and Method Statement (RAMS)

Many clients require a Risk Assessment and Method Statement (RAMS) before any work commences on their site. In simple terms a method statement is a safe work plan for a particular job or task and is the end product of a risk assessment. In the UK the Management of Health and Safety at Work Regulations require a risk assessment to be carried out before work can begin, with roped access being no different.

The modern and good practice approach to safety requires those responsible for any work to consider in advance the risks involved and plan accordingly to eliminate them wherever possible or at least control and minimise them to an acceptable level. When working on clients premises there is inevitably a degree of shared responsibility between those supplying the service and those responsible for the site and it is important to ensure that everyone involved has a clear understanding of their respective responsibilities.

The first stage in drawing up a rope access method statement is the risk assessment, for which two concepts need to be understood: hazard and risk.

What's a Hazard?

A hazard is something with the potential to cause harm. This can include chemical substances, methods of work, like rope access and the working environment.

What's a Risk?

Risk is a combination of the likelihood of that harm occurring and the severity of the consequences.

We all do risk assessments in our everyday lives without thinking about it. We look both ways before crossing the road and assess whether the speed and proximity of vehicles make it safe to cross. However to assess some risks may require specialist knowledge such as the consequences of being exposed to a particular substance. When assessing risk, emphasis should be placed on the severity of consequences. Even if the likelihood of harm occurring is low; the consequences may be such that the risk is unacceptable.

Remember that consequences may affect many people other than those directly involved in the work or in the immediate vicinity. For example a swinging load could injure someone nearby but if it struck and fractured a pipe in a chemical plant it could affect the entire neighbourhood or possibly worse.

The level of detail in a risk assessment should be proportionate to the risk. For all tasks the method statement should be formally prepared and written down so that it can be reviewed by all parties involved. Many clients will request the method statement prior to arrival on site so that they can consider what is to be done, how it is to be done and how it will affect them and, if necessary, request changes, usually in advance. In any event, having a work plan is useful in preparing for any problems that might arise and ensuring that everyone concerned is aware of what is to be done, how it will be done and the risks that might arise in the process.

One way of preparing a method statement is to have a model plan and consider how the operation and conditions vary from the norm, then, adapt the plan to the particular job.

Eliminating & Controlling Risk

If there is no hazard then there is no risk, so the obvious way of eliminating the risk is to remove the hazard. Taking the example of an acid cleaning fluid, it may be possible to use a detergent based cleaner instead as this has a significantly lower risk. Similarly using a purpose designed piece of lifting equipment, e.g. a lifting beam or a special clamp, may be much safer than trying to lift and manipulate a difficult load with general purpose slings. When working above people below, consider the consequences of accidentally dropping tools or materials. A rope access inspector with only a hand held torch can remove the hazard by attaching the torch it with a lanyard prior to working at height.

For many hazards it may be possible to reduce the risk to acceptable levels or eliminate it completely by substitution or by a change of working practice. However, this will not always be the case. There may be practical or economic reasons why the hazard remains and other steps will be necessary.

Considering again the cleaning fluid, whilst a detergent based product will have significantly lower risks some remain. If the operator wears protective gloves and safety glasses, then the risk of dermatitis or eye damage is reduced, even removed. When lifting equipment is used in adverse conditions, increasing the factor of safety and/or increasing the frequency of thorough examinations may control the risk. When working above people below, the risk to them, arising from falling tools and material can be controlled by a safety net or cordoning off the area below using barriers.

We can see from the above that the approach to be taken is logical. Remove the hazard if possible and, if it cannot fully be removed, reduce the risk to an acceptable level by processes, guards, PPE etc.

- Identify the Hazards

- Decide who may be harmed and how

- Evaluate the risk and decide on precautions

- Record your significant findings

- Review your assessment and update if necessary

How to Prepare a Rope Access Method Statement

For a complex job, break it down into a series of operations and prepare a method statement for each operation. Putting these together will form the method statement for the complete job. Every stage of each operation has to be considered.

First some research is required. We need to know what the site conditions are like in order to organise equipment and work procedures. For example, is it hot – cold – wet – difficult to access – restricted – noisy? Are there services in the work area that might present a hazard, e.g. gas – electricity – water? Is the lighting adequate? Is the floor, passageways and hard standing capable of sustaining any loads that might be imposed by rope access equipment etc?

A site visit may be necessary, not always, although its generally good practice to carryout a site visit to obtain sufficiently detailed information.

From this information a method statement can be prepared showing the equipment required, the sequence of events, the hazards identified and the risks arising from those hazards and the means of controlling them. It is advisable to build in a method for varying the plan, by agreement with the customer, to allow for changing site conditions, using dynamic risk assessments allows for changes. The method statement should be agreed with all parties involved and a record kept for any safety induction meetings that are held.

Contents of the method statement

- document title

- company details e.g. name, address, telephone numbers, email address document author

- health and safety contact person

- document traceability details, e.g. number; issue date;

- revision date and revision number

- site address

- site contact details, including emergency telephone numbers

- start date and completion date

- a description of the works, task or process detailing rope access as the method.

Dangle's Rope Access Equipment

Descenders

For personal or assisted rescue or descent

Self-braking descender for single rope, static, semi-static (EN1891) or dynamic (EN892) rope (of kernmantel construction). Diameters 10.5 to 13mm. Maximum descent distance 200m. Normal working load: 100kg. In exceptional circumstances (rescue) the maximum load can be increased to 200kg, additional friction braking will be required. Certified to EN12841 type C and EN341 class A.

For rescue and independent or assisted descent

Loads of over 150kg are not recommended because of possible high impact forces on other components of the system. I‘D certified to EN12841 type C and EN341 class A. Self-braking descender for single rope, static, semi-static (EN 891) or dynamic (EN892) rope (of kernmantel construction). Diameters 10.5 to 13mm. Maximum descent distance 200m. Normal working load: 100kg.

In exceptional cases, for example accompanied descents, the maximum working load indicated by the standard EN341 may be insufficient. Laboratory tests have shown that, with precautions taken in use (no impact force may occur), the I‘D can be handled with a load of up to 250 kg.

Harness

Integrated CROLL ventral rope clamp for ascending ropes.

Sternal attachment point can be used to connect a fall-arrest system and help ensure that the user is suspended in the correct position after a fall. One ventral and two lateral attachment points for multiple hands-free work positioning configurations. Can be used in conjunction with a work seat for prolonged suspension. Conforms to standards EN361 (fall arrest harness) EN 358, EN 12841 type B, EAC and EN813 (Work position harness). Minimum strength of 15kN on each D-ring.

Helmet

Lightweight helmet for work at height and rescue

Lightweight and comfortable helmet, meets requirements for work at height. Chinstrap designed to reduce the risk of the helmet coming off as a result of an impact during a fall, it has a breaking strength greater than 50daN (EN12492 mountaineering helmet standard). Meets the requirements of the EN397 and EN12492 standards for impact protection. Meets the requirements of the EN 397 and EN 50365 standards for electrical insulation. Meets the optional requirements of the EN 397 standard for molten metal spray, lateral deformation and use in low temperatures.

Ascenders

Petzl Ascension Handled rope clamp

Handle with ergonomic grip for comfort and thermal insulation. Trigger cam with teeth and cleaning slot: works even on dirty or icy ropes. Ergonomic spring-loaded catch is easy to use even when wearing gloves. Spring-loaded catch can be locked in the open position so the rope clamp can be put on or taken off the rope with one hand. Two holes on the bottom: one to connect a lanyard and one for installing a foot loop with a quick link. The upper holes allow a to be clipped so the rope clamp can be used for self-belaying or with hauling systems. Available in right and left-handed versions. Certification EN567 and EN12841 Type B.

Chest-mounted rope clamp to be used in conjunction with the ASCENSION for ascending a rope. Trigger cam with teeth and cleaning slot: works even on dirty or icy ropes. Ergonomic spring- loaded catch designed to facilitate installation/removal of rope when the device is in place on chest. Spring-loaded catch can be locked in the open position so the rope clamp can be put on or taken off the rope with one hand. The attachment hole is oriented so the device lies flat against the chest when clipped in. Certification EN567 and EN12841 Type B.

Connectors

The essential link in any rope access safety system, connectors vary according to their shape, size and locking system. The size of the gate opening determines what they can be clipped to. Aluminium connectors are made of an alloy ensuring an excellent strength to weight ratio. The heavier steel connectors are most often used in anchor systems and where durability is of importance. Certification EN362. Typical breaking strength 25kN.

Back Up Devices

Mobile fall arrester for rope access similar device to the ASAP but has a lock function to help keep the backup high and is easier and quicker to attach to and detach from the rope. Certification EN 353-2 and EN 2841 Type A

For use with 10.5 to 13 mm semi-static ropes (EN1891 type A) certified with the device.

What's Rope Access Equipment Certification?

All the rope access hardware equipment owned by a contractor should be individually numbered and traceable to a test certificate. The equipment is visually inspected by a competent person and certified as a minimum, on a six-monthly basis. Rope access work equipment and training equipment is inspected by a competent person every six months. This complies with Lifting Operations and Lifting Equipment Regulations 1998 (LOLER).

All equipment should be checked there after each time prior to being used on a project by the rope access team.

Care and Inspection of Rope Equipment

Hardware should be free from rust, and kept clean. The steel karabiners, maillons and wire slings should be cleaned with a wire brush and lubricated appropriately. The remainder of the hardware, (ascenders, descenders, back-ups etc.) which are alloy, should be cleaned and lubricated as required according to the manufactures care guide.

The hardware; ropes, harnesses, and tape slings etc should be cleaned in a low temperature wash (40°C or below) with a non-bleach soap, rinsed and dried naturally. The equipment should be stored in a cool, dry environment, away from direct sunlight as UV light can cause damage to synthetic threads.

Defective Working at Height Equipment

Any item of hardware showing excessive wear or damage or software showing signs of tears, cuts or abrasion should be quarantined and returned to stores with a non-conformance report for further inspection/repair. A non-conformance report is filled in and returned with the piece of equipment so that it is high-lighted to the materials controller. It is thus ensured that the piece of equipment is either repaired or withdrawn from service. If no rope access stores are available on-site usually the level 3 site safety supervisor is informed and he or she will remove the defective equipment from service and mark them item in question with "Do Not Use" and a date prior to placing in quarantine until such a time the rope access stores can be accessed.

About Dangle Rope Access

Here at Dangle, we provide a variety of comprehensive inspection, access, coatings, and composite (IACC) industrial services. Our services are available to both the private and public sectors.

We offer high-quality proven solutions that will help reduce maintenance costs in both the long and short-term. We are based in Dundee, Scotland and also have offices based in Edinburgh, along with our newly established training centre in Northern Ireland Dangle Academy. Due to our company size and structure, we are able to offer a flexible and versatile approach to the way we run our business and the services that we offer our clients. And, as a leading painting company, we’ve worked on several renewable energy projects in the UK, Europe, and the US.

We work with both on and offshore with wind farm operators, and asset owners. For offshore wind farm maintenance, to onshore building maintenance, we can cover both the East and West coasts.

To find out more about how our team can help you contact us today. Our friendly, professional and helpful team is always on hand to help.

Working at Height

High Level Access