Coating Experts

The Benefits Of Using Coating Experts

Protective Coating Systems

As humans, we undoubtedly became aware of corrosion right after making our first metals. Our late ancestors probably began to control "rusting" very soon after that by trying to keep their metals aware from corrosive environments.

Now the mechanisms of corrosion are better understood, more techniques have been developed to control it and paint is one of the most recognised methods used today.

The application of coatings systems is the most common and cost effective method used both onshore and offshore. Coating failures or corrosion initiation of a coated surface often occurs in areas where the paint was not correctly applied or has suffered from a form of mechanical damage resulting in exposure of the metallic substrate to the local environment.

Coating systems may integrate several layers of industrial paints, however the compatibility between coats must be ensured. The ideal coating system should assure the proper performance of the structure to which it is been applied during its service life without the need for often, very costly structural repair.

There are some major factors involved in the selection of a coating system and here at Dangle, using our expert coating consultancy knowledge we can guide you every step of the way, from initiation to completion.

What is the role of a coating consultant?

The role of a coating consultant is a broad one. In order to help select a coating system that is best tailored to a project and will provide the best possible performance and longevity, a coatings technical authority needs to evaluate and understand the needs of the project, the needs of the coating, and the regulatory and industry standards and local environment in which market the asset originates.

Dangle can provide this level of expertise and advice to ensure you and your assets are adequately protected, for years to come.

The benefits of using Dangle’s coating consultancy services

Our coating consultants have a broad remit. They’re the most knowledgeable and highly trained members of our team, forming part of Dangle's Board of Directors. That means they’ll be on hand for all aspects of a project, taking on the most complex tasks and providing support to the whole team at all times.

Before a project begins, a key task is writing the painting work specifications. These essential documents clearly lay out the materials and processes for the job. They include the types of paints and coatings to be used, and how surfaces should be prepared prior to painting. Plus the environmental conditions to be observed (think temperature and humidity, for example). They’ll also cover the maximum time interval between surface preparation and priming, as well as between coats. There’s also the number and thickness of coats which all should be recorded and the list goes on...

To prepare an industrial paint specification, the consultant starts with the project requirements. And factors in regulations and other industry standards, as well as the latest types of paints and coatings available on the market. However, this investment pays dividends when it comes to ensuring long-lasting, quality work.

Dangle's expert team of coating and paint consultants hold advanced, industry-recognised qualifications. The National Association of Corrosion Engineers formally known as NACE but having recently merged with the Society of Protective Coatings (SSPC) to form AMPP ( Association for Materials Protection and Performance ) is now the worlds leading authority on setting the benchmarks for industrial coatings worldwide. We’re also members of the Institute of Corrosion (ICORR) here in the UK and you'll see our team hard at work on their websites homepage. With training courses and Level 3 qualifications from both organisations guaranteeing a high level of expertise and Charted status for professional peace of mind.

The consultants’ role doesn’t end there. Paint failure analysis is another highly skilled task, often involving very specialised equipment and standardisation knowledge. Coatings and paints provide long-term protection for a structure - and the investment of the asset owners. Paint failure may become noticeable through blistering, erosion or similar. Understanding the causes is key to avoiding the same faults in the future.

The most common causes of paint failure start with incorrect surface preparation. Followed by inadequate environmental conditions. The application method and formulation are also key factors. Formulation includes the cure time and amount of product used, amongst other things, like risk to waterways and the local environment through VOC's (Volatile Organic Compounds). Weighing up all of these factors during analysis requires expert trouble shooters, with decades of experience.

Marine grade paint specifications are a particularly specialised area and we discuss these and the most recent changes in our blog post on ISO12944 . Harsh conditions at sea pose many additional challenges that are not as prevalent on land. For example, corrosion on underground pipelines could be due to microbiological-influenced corrosion (MIC) and many coating standards are developed for use by a wide range of industries. This means marine paint specifications may not actually be the most suitable specification for onshore structures and may pose a particular challenge if designed for the wrong environment. Consultants need specialist experience to develop effective solutions, which is what we offer here at Dangle!

Do you need an exterior paint consultant? Help with epoxy paint for steel surfaces or a structural steel paint specification? You’re in the right place. We do all those too.

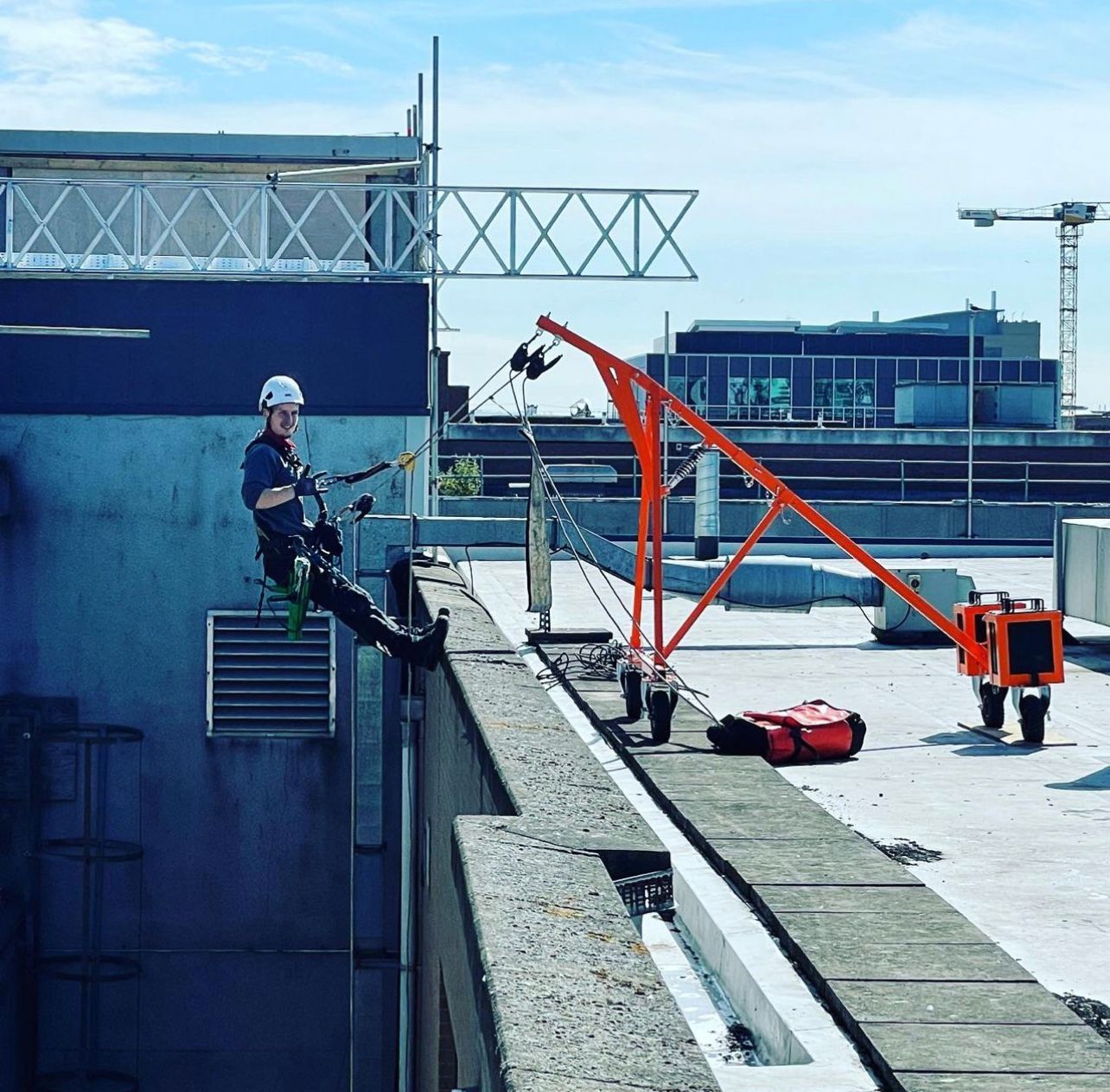

Dangle is an award-winning, family-run business. Our relative size gives us more agility than many larger companies. It means we always offer a flexible and tailored approach. We have many years of industrial inspection, access, coatings and composite (IACC) experience. Our team also comprises expert rope access technicians. This means we can access difficult-to-reach areas quickly and safely. And we’ll always integrate seamlessly with your teams to come up with the most effective solutions.

About Dangle Rope Access

Here at Dangle Rope Access, we provide a variety of comprehensive inspection, access, coatings, and composite (IACC) industrial services. Our services are available to both the private and public sectors.

We offer high-quality proven solutions that will help reduce maintenance costs in both the long and short-term. We are based in Dundee, Scotland and also have offices based in Edinburgh, along with our newly established training centre in Northern Ireland Dangle Academy. Due to our company size and structure, we are able to offer a flexible and versatile approach to the way we run our business and the services that we offer our clients. And, as a leading painting company, we’ve worked on several renewable energy projects in the UK, Europe, and the US.

We work with both on and offshore with wind farm operators, and asset owners. For offshore wind farm maintenance, to onshore building maintenance, we can cover both the East and West coasts.

To find out more about how our team can help you contact us today. Our friendly, professional and helpful team is always on hand to help.

Paint Failure Analysis

Coating Consultants

We'd love a share...