What is ISO-12944

What is ISO12944?

Corrosion Protection

ISO12944 is widely recognised as the internationally accepted industry standard for the corrosion protection of steel structures through the use of protective paint systems. First introduced in 1998, this comprehensive standard has been meticulously compiled by representatives from various countries and companies that are deeply involved in the safeguarding of steel structures, thereby ensuring a mutually beneficial set of guidelines.

The primary objective of ISO12944 is to offer valuable guidance to a wide range of professionals, including architects, engineers, specifiers, applicators, and other stakeholders involved in the process of applying coatings to steel. By adhering to the principles outlined in this standard, these individuals can effectively protect steel structures from the detrimental effects of corrosion.

Comprising of nine essential parts, ISO12944 encompasses a plethora of crucial components that are fundamental to the successful implementation of corrosion protection measures. These components include but are not limited to environment classification, protective paint systems, laboratory test methods, and systems and test methods specifically tailored for offshore structures.

In essence, ISO12944 serves as a comprehensive and indispensable resource, empowering professionals within the industry to make informed decisions regarding the selection, application, and evaluation of protective paint systems for steel structures. By following these guidelines, they can ensure the longevity and durability of these structures, even in the harshest of environments, whilst simultaneously contributing to the overall safety and sustainability of the built environment.

What has changed in the 2018 edition of the standard?

In the latest release there are a number of significant changes to the standard. These changes are:

1) The old C5-I and C5-M categories have been replaced with C5 for harsh onshore categories and by CX for offshore categories. CX is taken care of in a new Part 9. There is also the addition of a fourth immersion category, IM4, which covers immersed structures in sea or brackish water which are protected by cathodic protection

2) The low, medium and high categories remain but they are joined by very high. The durations which these categories relate to have also changed with low durability now up to 7 years and the new very high category relating to 25 years plus.

3) The dry film thicknesses and paint systems now include a minimum number of coats per coating type or technology and specify a minimum dry film thickness for the total system per corrosion category. The standard now also includes the capacity to accept new innovative coating technologies if performance can be demonstrated by 3rd party testing and field trials.

4) Up to C4 high the test methods have not changed. However for C4 very high, C5 high and C5 very high, cyclic testing has been introduced to better replicate in-field conditions.

Why has cyclic testing been introduced?

One of the significant changes in the newest revision is the addition of cyclic testing for systems operating in environments of C4 very high and above. This addition to the standard has been warmly received by most coating manufacturers, as they have discovered over the course of many years that cyclic testing provides a more accurate representation of real-world corrosion conditions. To assess the effectiveness of three coating systems, extensive testing was conducted, including long-term static salt fog testing and a variety of cyclic test methods, all compared against an in-service field trial.

The results of these tests were quite revealing. While certain systems demonstrated satisfactory performance during the salt fog testing, their performance did not match up to those systems evaluated through cyclic testing or under real-world conditions. This finding underscores the importance of incorporating cyclic testing into the evaluation process, as it better simulates the dynamic and fluctuating nature of corrosion in practical settings.

By implementing cyclic testing, the newest revision addresses a crucial aspect of coating performance assessment that was previously overlooked. Coating manufacturers, who have long recognized the limitations of solely relying on salt fog testing, appreciate the inclusion of this more comprehensive evaluation method. The new approach acknowledges the fact that corrosion conditions in the real world are rarely static and continuously change due to various environmental factors.

The decision to introduce cyclic testing into the standard was not made lightly. Extensive research and comparisons were conducted to ensure its validity and reliability. The inclusion of this testing method is a testament to the continuous improvement and evolution of industry standards, aiming to provide more accurate and reliable data for coating performance evaluations.

Furthermore, the addition of cyclic testing will likely have a positive impact on the industry as a whole. Coating manufacturers can now develop products that are better suited for real-world conditions, resulting in enhanced corrosion protection and longer-lasting coatings. Ultimately, this will benefit end-users who rely on these coatings to safeguard their assets and infrastructure from the detrimental effects of corrosion.

In conclusion, the newest revision of the standard introduces the much-needed inclusion of cyclic testing for systems operating in high-corrosion environments. This change acknowledges the shortcomings of relying solely on salt fog testing and emphasizes the importance of evaluating coatings under dynamic and fluctuating conditions. Through this comprehensive approach, manufacturers can develop more reliable and effective coatings, ensuring superior corrosion protection in real-world scenarios.

ISO 12944 Part 9?

The introduction of Part 9 to the ISO12944 standard brings about a significant development by incorporating the old ISO20340 standard into ISO12944. This new addition places emphasis on the use of cyclic testing for offshore structures. In the previous editions of the standard, offshore structures were referred to as C5-M. However, a noteworthy change has been introduced with the introduction of a new environmental category, CX, that applies to all offshore structures.

Under Part 9, all offshore systems are required to undergo 4,200 hours of cycling testing, which equates to approximately 25 weeks. This stringent testing ensures that the coating systems used in offshore structures meet the necessary durability requirements. Additionally, Part 9 sets out the minimum number of coats and minimum film thickness per system, with some modifications from the previous standard's requirements for C5-M. The following table provides an outline of the specific requirements for steel substrates.

One of the key differences between ISO12944 Part 9 and ISO20340 is evident in the performance criteria for corrosion creep. Part 9 now stipulates that coating systems for high impact areas should be less than or equal to 8.0mm, while all other CX applications should be less than or equal to 3.0mm. Moreover, the pass criteria for sea water immersion has been set at 6.0mm, and there have been slight adjustments to the adhesion requirements as well. These updates ensure that the coating systems used in offshore structures are able to withstand the harsh conditions they are exposed to.

About Dangle Rope Access

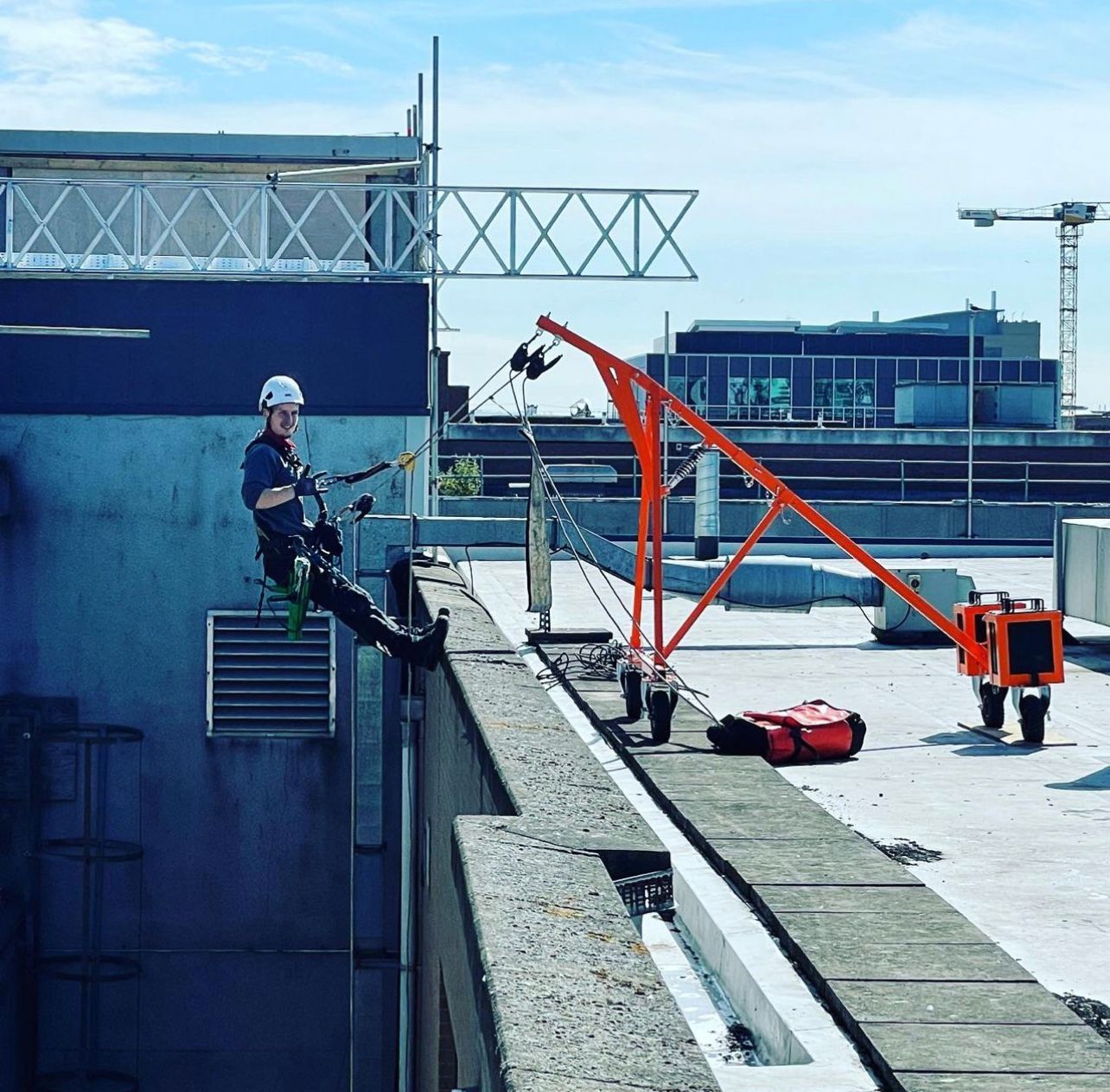

Here at Dangle Rope Access, we provide a variety of comprehensive inspection, access, coatings, and composite (IACC) industrial services. Our services are available to both the private and public sectors.

We offer high-quality proven solutions that will help reduce maintenance costs in both the long and short-term. We are based in Dundee, Scotland and also have offices based in Edinburgh, along with our newly established training centre in Northern Ireland Dangle Academy. Due to our company size and structure, we are able to offer a flexible and versatile approach to the way we run our business and the services that we offer our clients. And, as a leading painting company, we’ve worked on several renewable energy projects in the UK, Europe, and the US.

We work with both on and offshore with wind farm operators, and asset owners. For offshore wind farm maintenance, to onshore building maintenance, we can cover both the East and West coasts.

To find out more about how our team can help you contact us today. Our friendly, professional and helpful team is always on hand to help.

Protective Paint Systems

Steel Structures