Coating Failure Analysis

COATINGS FAILURE ANALYSIS

Coating Failure Analysis and the Investigation of Protective Coatings in Wind, Marine Offshore Oil & Gas, Chemical Plants, Energy Infrastructure, Bridges and Mining (Ask the Experts) topic.

Critical Questions we often get asked on Protective Coatings used for Asset Protection in industrial fields such as Oil & Gas, Renewable Wind Energy etc when applied by painting companies are:

- Why is the coating not stopping corrosion?

- Why is the coating delaminating or blistering?

- Has the coating been correctly specified and/or correctly applied by the paint contractor?

- Does the coating meet the manufacturing standard, including properties such as correct hardness/cure, adhesion and thickness?

- What surface preparation and atmospheric conditions must be achieved to successfully apply the industrial paint?

- Does the coating have any defects in it? How will these affect performance and can you quality check?

- Why did the coating fail? Root cause assessment.

- How can the coating be successfully repaired/remediated so that it doesn’t fail again?

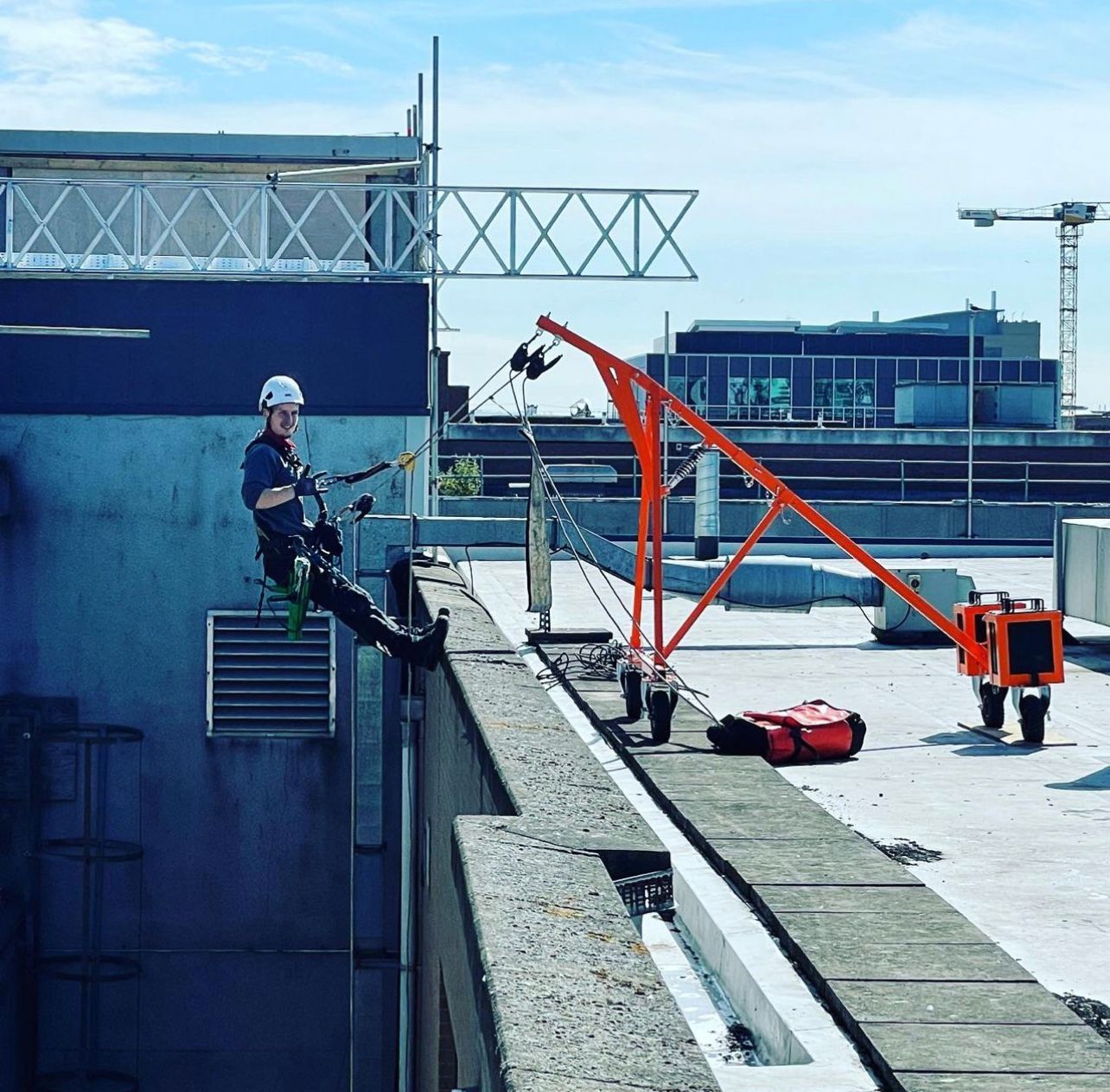

Coatings Inspection & Testing is a method that conducts coating condition assessment and testing for clients across all sector. It provides conventional and advanced non-destructive testing services, as well as destructive & chemical testing on a range of protective coatings. Dangle has qualified coatings specialists supported by materials, equipment and corrosion analysis software to inspect, analyse and assess protective coatings.

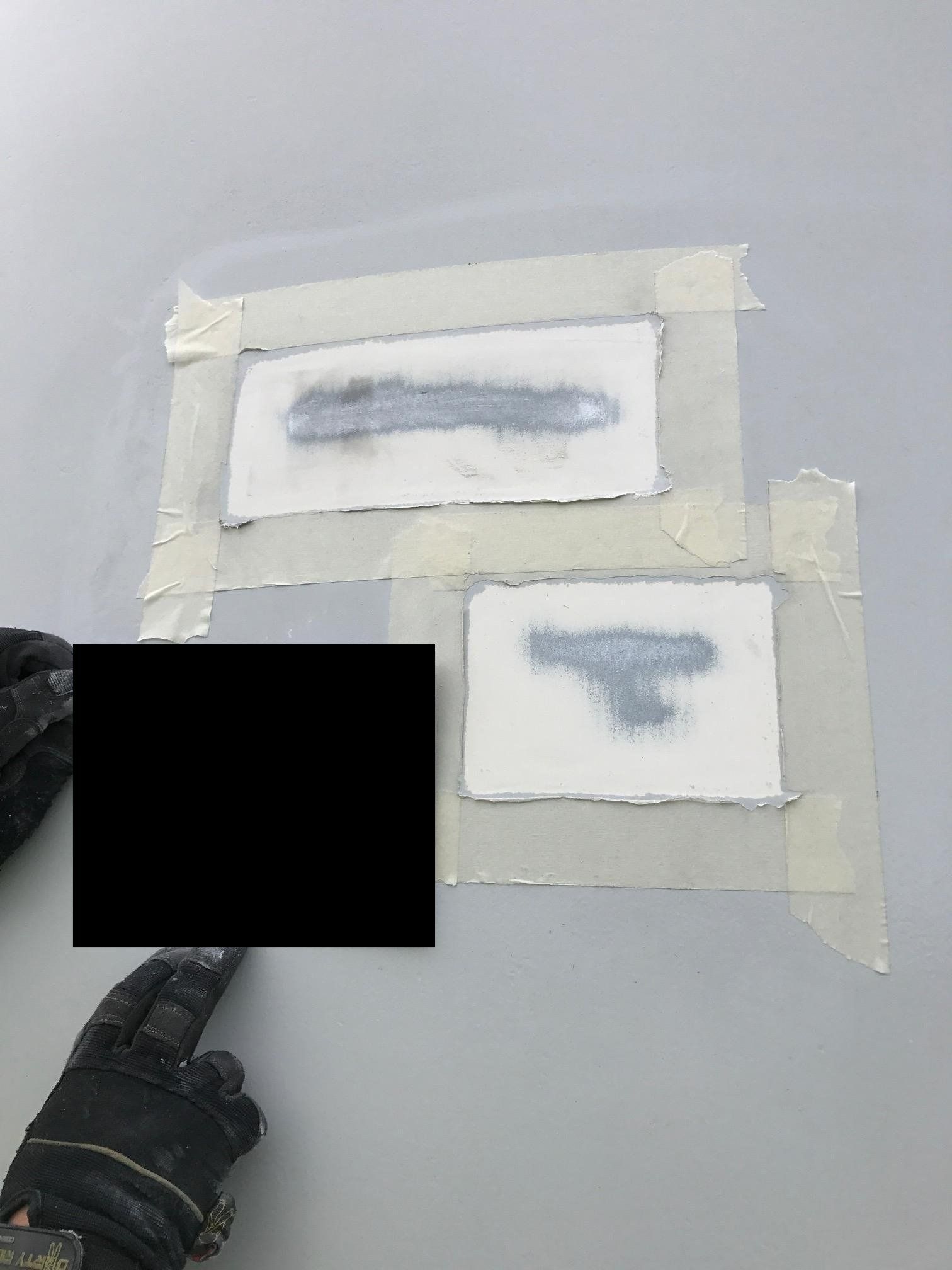

We offer: • specification and selection of protective coatings • accelerated weathering, salt spray and humidity testing and screening of candidate coatings • coating inspections including hardness, DFT thickness, X-cut adhesion, pull-off adhesion, holiday testing, wet-sponge testing, surface roughness, etc. • investigation and analysis of coating failures (root cause) • coating repair strategy and approach (i.e. type of surface prep, selection and screening of reinstatement coatings)

Coatings Testing by Dangle Rope Access provides protective coating analysis services and various laboratory testing on protective coatings. The combination of our experienced coatings chemists and corrosion technologists together with our material scientists ensures that the client receives the best test regime in accordance with various international Standards. Dangle is working towards its accredited status with ISO 17025 in some of the laboratory-based coating related tests. We dont just say we're experts in the field of industrial painting, we can deliver and provide the following types of inspections and laboratory based tests on coating • Blast surface inspection – blast profile measurements using Testex method • Pre-coating surface inspection reporting for soluble salts contamination. • Dry Film Thickness (DFT) • Degree of cure testing (DoC) • Coating Adhesion test (coating Pull-off testing, POT) • Film continuity test (Low Voltage Wet Sponge) • Holiday (high-voltage porosity) coating continuity test • Coating qualification testing • Cathodic Disbondment (CD) tests • Field Based Failure (FBF) investigation on coatings • Third Party Inspection and witnessing of coating activities.

EIS Testing - EIS is a technique well suited for evaluating the permeability or barrier properties of protective coatings based on the electrical resistance of the coating. The impedance of a coating is related to the nature of the polymer, its density, and its fillers. The impedance of a coating is observed to decrease as a function of time of exposure in the service environment. The decrease in impedance is observed to be related to the formation of microcracks, fissures, galleries, loss of barrier properties and the onset of under-film corrosion. As protective coatings such as epoxies and epoxy-phenolics age they become more permeable to ions, water, gases, and other corrosive species of the service environment. EIS thus tracks the barrier properties of the coating and can give information on the state of the coating and its expected service life.

Coating Micro-structural Analysis - can undertake micro-structural examination of protective coatings to determine their quality and integrity. The micro-structural examination involves evaluating coating thickness and number of layers, identifying filler/pigment size and distribution, pigment agglomerates, oxide clusters, micro-cracks, identifying and quantifying of voids or porosity, foreign particles, interface appearance, delaminations, corrosion cells etc. Here at Dangle we routinely perform micro-structural examination of protective coatings frequently for its clients in the oil & gas, mining, pipelines and offshore sector.

Protective Coating Inspection Services for: Mining industry infrastructure (Tanks and Pipes) Oil and Gas industry infrastructure Offshore structures FPSO Above & Below Ground Gas and Oil Transmission Pipelines, Process Piping, Storage tanks Water & Waste Water Treatment Plants Aviation and Airport facilities (Fire Fighting Foam Storage Tanks) Pipeline Coating Types: • Liquid applied epoxy (LAE) coatings • Fusion bonded epoxy (FBE) powder coatings • Polymeric tape coatings • Bituminous tape coatings • Petrolatum and wax tape coatings • Heat shrinkable coatings • Elastomeric coatings • Automobile coatings (epoxies) • Coil coatings (polyester) • Construction coatings (epoxies, polyurethanes) • Fluorocarbon coatings (PVDF) • Plastic coatings • Powder coatings • Rubber paint

Founded in 2013, Dangle began conducting coating condition assessment and testing for major clients in the oil & gas sector using rope access. We provide conventional and advanced non-destructive testing services, as well as destructive & chemical testing. Coatings Problem Solving Protective Coatings are an essential component billion-pound fight against corrosion and damage or steel plant, equipment, vessels and pipelines.

Dangle can assist clients and asset owners to address coating problems and questions such as: • Has the protective coating been correctly specified and applied? • What level of surface preparation and atmospheric conditions are required to ensure the coating performs properly in service? • Why is the coating not acting as a corrosion barrier? • Why is the coating swelling, blistering and/or delaminating? • Does the coating meet the product/project specifications for correct thickness, correct hardness, adequate degree of cure and adequate adhesion? • Does the coating have any defects in it such as pigment agglomerates, voids, air bubbles, inclusions? How will these defects affect performance? • By what mechanism did the coating fail? • How can the failed coating be remediated/replaced so that it doesn’t fail again?

Epoxy Mix Ratio Testing Epoxy-based coatings can fail if incorrect ratios of the base epoxy and amine hardener that form the epoxy coatings are used. Dangle can also conduct nitrogen analysis testing to confirm the mix ratios of in service epoxy coatings, if this is a client concern.

There are many levels and layers involved with industrial painting projects when it comes to coating failure analysis, its extremely important only those property trained and qualified are tasked with finding the root cause(s).

About Dangle Rope Access

Here at Dangle Rope Access, we provide a variety of comprehensive inspection, access, coatings, and composite (IACC) industrial services. Our services are available to both the private and public sectors.

We offer high-quality proven solutions that will help reduce maintenance costs in both the long and short-term. We are based in Dundee, Scotland and also have offices based in Edinburgh, along with our newly established training centre in Northern Ireland Dangle Academy. Due to our company size and structure, we are able to offer a flexible and versatile approach to the way we run our business and the services that we offer our clients. And, as a leading painting company, we’ve worked on several renewable energy projects in the UK, Europe, and the US.

We work with both on and offshore with wind farm operators, and asset owners. For offshore wind farm maintenance, to onshore building maintenance, we can cover both the East and West coasts.

To find out more about how our team can help you contact us today. Our friendly, professional and helpful team is always on hand to help.

We'd love a share...