Falls From Height Rise 2021

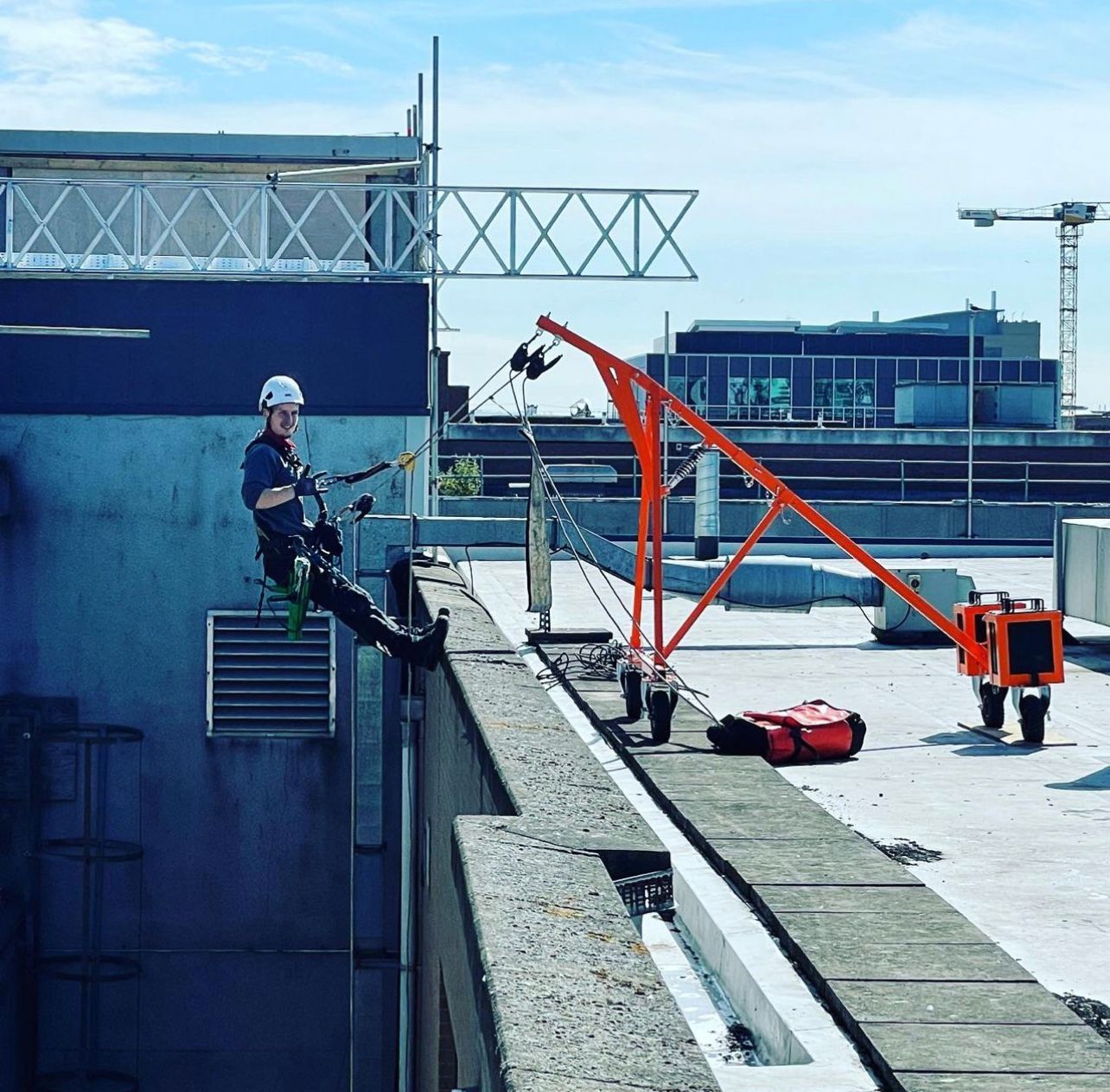

Fall Protection Equipment Saves Lives when Operated by Correctly Trained Personnel...

The latest figures are in...

Working at height tragically, within the onshore scaffolding and construction sectors, encountered 39 fatal injuries to workers and 4 to members of the public in 2020/21. This was a rise from the previous annual average of 36.

And you may’ve already guessed it... Falls from height was a major source of those fatalities, contributing to 50% overall. There were also 61,000 non-fatal injuries, 19% of which were attributed to falls from height.

Thankfully these numbers are much lower than decades previous, highlighting the stringent health and safety protocols now in place that have helped the UK cultivate an improved safety culture. But to push that trend down instead of up, we must keep banging the height safety drum. In this guide, we take a look at the ABCs of fall protection, and advise what fall protection equipment you need to stay safe when working at height carrying out Rope Access work onshore.

What is fall protection equipment?

If you’re working on a project that requires operations at height, fall protection equipment is a requirement to help you conduct your work with ease, while simultaneously preventing any serious injuries or fatalities.

Think safety harnesses, fall restraint lanyards, and work positioning two points of contact. It’s this type of gear you and your rope access teams need to prevent a fall. But it’s important to use the correct equipment for your particular scenario.

An important first step before undertaking any work at height is therefore assessing the threats and risks. This will help you identify if the work at height is necessary and what dangers you might encounter, helping you procure and deploy fall protection equipment that will keep you or your teams safe. This review and assessment process must be undertaken by a competent and qualified person, At Dangle, we carryout a Toolbox Talk and Dynamic Risk Assessment before every task, no matter how big or small the job.

The ABCs of fall protection

Fall protection equipment consists of three different categories: fall restraint, fall arrest, and work positioning systems. Each of these categories follow the ABC’s of fall protection:

- Anchorage – Anchoring is a security point of attachment (usually to a "unquestionably sound" structure) for the fall arrest system to anchor from.

- Body support – A full body harness provides a connection point on the rope access technician for the fall arrest system.

- Connection method – Connectors, such as fall restraint or fall arrest lanyards, are used to connect the rope access workers body support equipment to the anchorage system.

Fall Restraint Systems

The safest form of protection is to first consider if it’s necessary to work at height in the first place. If possible, your first port of call should be to carry out your work with two feet firmly on the ground, if that is the safest option, which isn't always possible.

Once it has been deemed essential to conduct work at height, a fall restraint system should be used to prevent a fall from occurring. A fall restraint system is often utilised in facilities management and on rooftops to create a safe working environment. It essentially restricts the wearer from entering dangerous zones where a fall could happen, usually at an edge of a building.

A fall restraint system should include:

Anchorage - a suitable anchor point, tested to EN795 for Restraint or Fall Arrest.

Body support - a work positioning or restraint belt, or a full body harness.

Connection method - a restraint lanyard or work positioning system such as a Petzl Grillon.

Fall Arrest Systems

A fall arrest system allows workers the freedom to move wherever they need to perform the job. Where this differs from a fall restraint solution is that it does allow a worker to reach a position where an accidental fall could occur and the rope access worker may then be held in suspension.

If a fall does take place, a fall arrest system is there to ensure a worker is caught before falling any distance that may cause severe harm. The required equipment must be chosen correctly and located in a manner that limits the distance a worker can fall, therefore reducing the risk of serious injury.

A suitable fall arrest system should include:

Anchorage - a suitable anchor point, tested to EN795 for Fall Arrest.

Body support - a full body harness.

Connection method - a fall arrest lanyard, energy absorbing lanyard or a self-retracting lifeline.

Work Positioning Systems

A work positioning system must keep a worker in place, while concurrently allowing the rope access technician to work hands-free. If the user is at an elevated height, a fall arrest system should be used in conjunction with the work positioning system to ensure that, if there is a user error or failure of the work positioning equipment, a fall can still be prevented. All IRATA rope access work conducted by Dangle is performed in such a way that a back up safety life in addition to a main working line is installed.

A suitable work positioning system should include:

Anchorage - a support structure such as a vertical rod.

Body support – work positioning/full body harness with suitable attachment options.

Connection method - a positioning lanyard such as a Petzl Grillon.

Don’t be a Statistic – Protect Your Team with the correct Fall Protection Equipment!

We all know that working at height presents many dangers. We must understand what those dangers are in order to effectively mitigate against them. Businesses that excel at implementing stringent safety measures, and who choose the most appropriate fall protection equipment, will be successful in reducing to risk of injuries to workers. Here at Dangle Rope Access were experts when it comes to working at height and can advise, install and inspect on a whole manner of working at height equipment.

About Dangle Rope Access

Here at Dangle Rope Access, we provide a variety of comprehensive inspection, access, coatings, and composite (IACC) industrial services. Our services are available to both the private and public sectors.

We offer high-quality proven solutions that will help reduce maintenance costs in both the long and short-term. We are based in Dundee, Scotland and also have offices based in Edinburgh, along with our newly established training centre in Northern Ireland Dangle Academy. Due to our company size and structure, we are able to offer a flexible and versatile approach to the way we run our business and the services that we offer our clients. And, as a leading painting company, we’ve worked on several renewable energy projects in the UK, Europe, and the US.

We work with both on and offshore with wind farm operators, and asset owners. For offshore wind farm maintenance, to onshore building maintenance, we can cover both the East and West coasts.

To find out more about how our team can help you contact us today. Our friendly, professional and helpful team is always on hand to help.

We'd love a share...