What Does a Blade Repair Technician Do?

What Does A Blade Repair Technician Do?

A Blade Repair Technician is a specially-trained engineer responsible for maintaining, repairing and inspecting the blades on a wind turbine. This work can be carried out onshore, offshore or in blade factories.

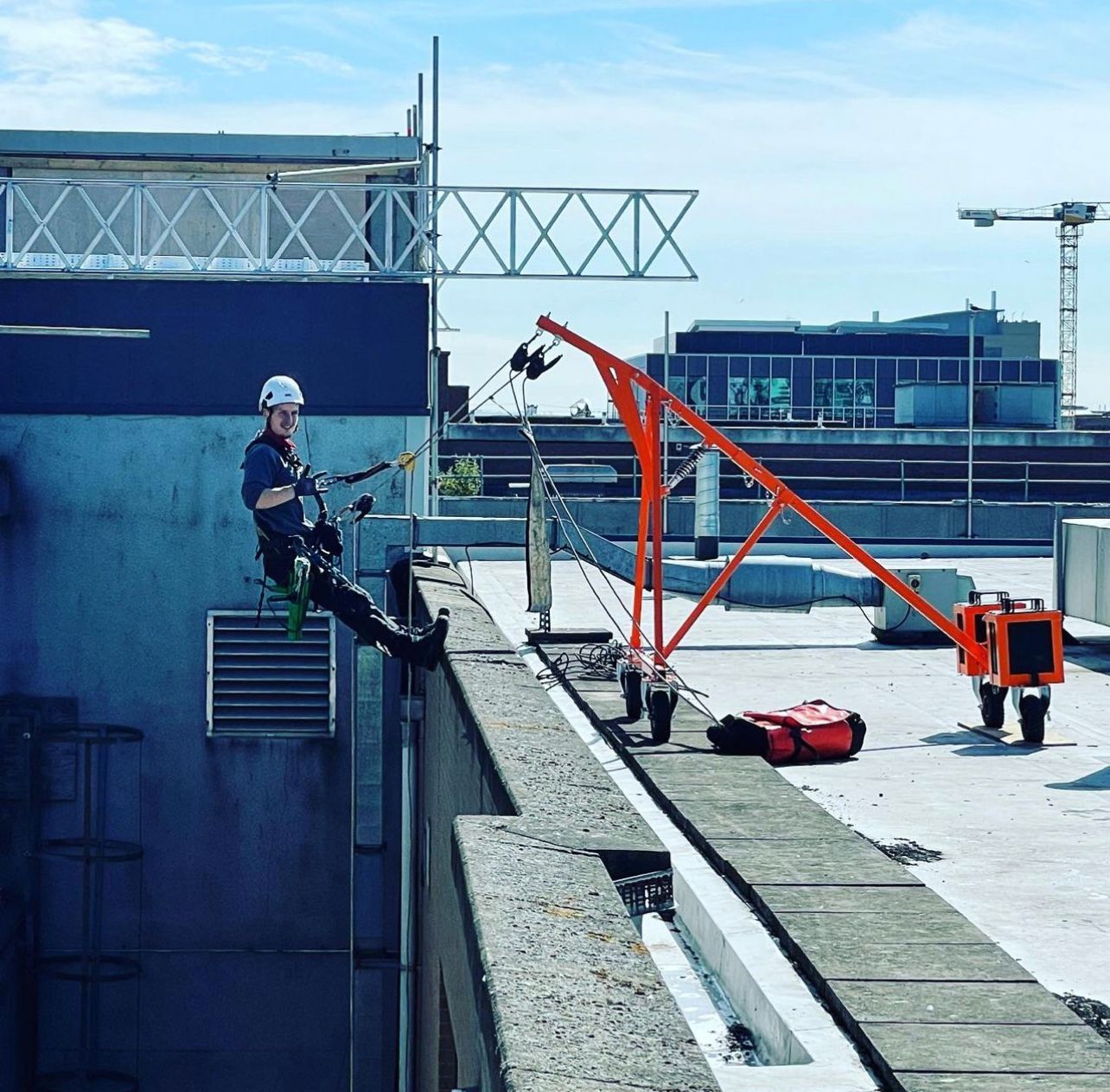

At Dangle Rope Access, our highly skilled blade repair technicians are equipped with the expertise and tools to effectively repair wind turbine blades. Our technicians follow a meticulous process to ensure optimal performance and longevity of your blades. They start by carefully inspecting the blades for any damage or wear, this can be done from the ground using drones as part of a wind farm drone inspection survey, or done from ropes if you prefer a more hands on approach. Once blade repairs are identified, they will use their rope access skills to safely access the blades for repair work. This may involve removing and replacing damaged sections if required, repairing cracks or delamination, and applying protective coatings. Our blade repair technicians are trained to the latest GWO (Global Wind Organisation) industry standards and techniques, guaranteeing only the best results. With Dangle Rope Access, you can trust that your wind turbine blades are in capable hands, reducing maintenance costs and maximising efficiency.

A blade repair technician is a specialised professional who is responsible for the maintenance and repair of wind turbine blades. These technicians play a crucial role in ensuring the optimal performance and longevity of wind turbines in general.The primary task of a blade repair technician is to inspect, identify, and repair any damages or defects in wind turbine blades. This includes conducting visual inspections, using specialised tools and equipment to assess the condition of the blades, and performing necessary repairs or replacements.

GWO blade repair training is often required for these technicians to ensure they have the necessary skills and knowledge to carry out their duties safely and effectively. This training covers various aspects such as working at heights, handling hazardous materials, composite repairs, and other technical skills specific to wind turbine blade repair. In addition to repairs, blade technicians may also be involved in preventive maintenance activities such as cleaning the blades, applying protective coatings or sealants, testing LPS (lightening protection systems) and conducting regular inspections to identify potential issues before they escalate into major problems. A blade repair technician plays a critical role in maintaining the efficiency and reliability of wind turbines by ensuring that their blades are in optimal condition. Their expertise helps maximise energy production while minimising downtime due to blade-related issues.

A blade repair technician plays a crucial role in the wind energy industry, specifically in the maintenance and repair of wind turbine blades. In this comprehensive guide, we will delve into the responsibilities and skills required of a blade repair technician, as well as the training and certifications necessary to excel in this field. GWO blade repair training is essential for aspiring technicians. This specialised training equips individuals with the knowledge and practical skills needed to safely carry out repairs on wind turbine blades. A blade repair technician must have a strong understanding of aerodynamics, composite materials, and structural analysis to effectively assess and address any damage or wear on the blades.

So what does a blade repair technician do? Their primary responsibility is to inspect, assess, and repair any damage sustained by wind turbine blades. This can include repairing cracks or fractures, replacing damaged sections of the blade, or addressing issues related to erosion or lightning strikes. Additionally, they may need to perform preventive maintenance tasks such as cleaning and applying protective coatings to enhance blade performance and longevity. To become a successful blade repair technician, one must possess excellent technical skills along with physical fitness due to the nature of working at heights. Attention to detail is crucial when identifying potential issues that may impact turbine performance or safety. Moreover, effective communication skills are essential when collaborating with other team members during repairs or reporting findings.

Wind energy continues to grow as an important source of renewable power generation globally. As such, the demand for skilled professionals like blade repair technicians is expected to increase significantly in the coming years. By following this comprehensive guide and obtaining relevant training and certifications such as GWO blade repair accreditation, aspiring technicians can position themselves for success in this dynamic field.

The Essential Guide to Becoming a Blade Repair Technician in the Wind Energy Industry

Understanding the role of a Blade Repair Technician and their importance in wind energy is an important one, for anyone aspiring to become a blade repair technician in the rapidly growing field of wind energy. Blade repair technicians play a crucial role in ensuring the smooth operation and longevity of wind turbines. As the demand for renewable energy sources continues to rise, understanding the importance of these skilled professionals becomes paramount.

A blade repair technician is an essential member of a wind turbine maintenance team. They are responsible for inspecting, repairing, and maintaining the blades that harness the power of wind to generate electricity. Their expertise and attention to detail are vital in keeping these towering structures operating efficiently and safely.

The wind energy industry heavily relies on blade repair technicians to address any issues that may arise with turbine blades. These professionals possess specialised knowledge in composite materials, structural integrity, and aerodynamics – all critical factors in maximising turbine performance.

The importance of blade repair cannot be overstated. Wind turbine blades are subjected to various environmental factors such as extreme weather conditions, erosion from airborne particles, and even lightning strikes. Over time, wear and tear can occur, leading to reduced efficiency or potential safety hazards if left unattended.

By regularly inspecting and repairing turbine blades, technicians help maintain optimal performance levels while minimizing downtime due to unexpected failures. This proactive approach ensures that wind farms continue to operate at their full capacity, providing clean and sustainable energy for communities around the world.

Blade repair technicians play a vital role within the wind energy industry by ensuring the proper functioning and longevity of wind turbines. Their expertise in maintenance and repairs helps maximise efficiency while contributing towards a greener future powered by renewable energy sources.

The Skills and Qualifications Required to Become a Successful Blade Repair Technician

Becoming a successful blade repair technician in the wind energy industry requires a specific set of skills and qualifications. These professionals play a crucial role in maintaining the efficiency and safety of wind turbines by inspecting and repairing the blades.

One of the key skills required for this role is expertise in blade repair techniques. This includes knowledge of various repair methods, such as leading edge erosion repairs, trailing edge repairs, and lightning strike repairs. Being able to identify damage and determine the appropriate repair technique is essential to ensure the longevity and performance of wind turbine blades.

In addition to blade repair skills, aspiring technicians should possess qualifications as a wind turbine technicians. This typically involves completing a specialised training program set-out by GWO that covers topics such as electrical systems, hydraulic systems, mechanical components, safety procedures, and troubleshooting techniques specific to wind turbines.

Furthermore, a deep understanding of composite materials is crucial for blade repair technicians. Wind turbine blades are commonly made from composite materials such as fibreglass or carbon fibre reinforced polymers. Knowledge of these materials' properties, manufacturing processes, and inspection techniques is essential for assessing damage accurately and selecting appropriate repair methods.

To sum up, successful blade repair technicians require a combination of technical skills such as proficiency in blade repair techniques and composite material knowledge. Additionally, obtaining relevant qualifications such as a GWO wind turbine technician provides foundational knowledge necessary for performing maintenance tasks on these complex WTG machines effectively.

The Step-by-Step Process of Repairing Damaged Wind Turbine Blades

Repairing damaged wind turbine blades is a crucial part of maintaining the efficiency and longevity of these renewable energy sources. The process involves several steps that need to be followed carefully to ensure a successful repair.

The first step in the wind turbine blade repair process is to assess the damage. This involves inspecting the blades for any signs of leading edge erosion or bond line delamination. Leading edge erosion occurs when the outer surface of the blade is worn down due to exposure to harsh weather conditions, while bond line delamination refers to separation between layers of materials that make up the blade structure.

Once the damage has been assessed, the next step is to prepare the damaged area for repair. This typically involves cleaning and removing any loose or damaged material from the affected area. This ensures a clean surface for proper adhesion during the repair process.

After preparing the damaged area, repairs can be made using various techniques and materials depending on the type and extent of damage. Dangle only use products from the world leader - Sika, for composites repairs to wind turbines.

For leading edge erosion repair, protective coatings, soft shell or filler materials can be applied to restore smoothness and aerodynamic performance.

Bond line delamination repair can be fixed by injecting adhesive materials into the separated layers and applying pressure or heat for bonding.

Once repairs have been made, rotor balance adjustments may be necessary to ensure proper functioning of the wind turbine system as imbalances in rotor blades can cause vibrations and reduce overall performance. Balancing techniques involve adding or removing weight from specific areas of each blade until they are properly balanced.

In conclusion, repairing damaged wind turbine blades requires a step-by-step approach that includes assessing damage, preparing surfaces, making repairs using appropriate techniques and materials, and performing rotor balance adjustments if necessary. Following this process diligently helps maintain optimal performance and extends the lifespan of these essential renewable energy components

Common Challenges Faced by Blade Repair Technicians and How to Overcome Them

Blade repair technicians play a crucial role in the maintenance and repair of wind turbine blades. However, their job is not without its challenges.

In this section, we will explore some of the common challenges faced by blade repair technicians and look at effective strategies to overcome them.

One of the primary challenges faced by these technicians is working at heights. Repairing wind turbine blades often requires working at significant heights, which can be dangerous if proper safety measures are not followed. It is essential for technicians to receive comprehensive training on fall protection and or rope access systems and equipment usage. Regular safety inspections should also be conducted to ensure that all safety protocols are being followed.

Another challenge that blade repair technicians encounter is extreme weather conditions. Wind turbines are often located in remote areas where weather conditions can be harsh and unpredictable. To overcome this challenge, it is crucial for technicians to closely monitor weather forecasts and plan their work accordingly. They should have access to appropriate protective gear such as insulated clothing, gloves, and water to protect themselves from extreme cold or heat.

Additionally, establishing clear communication channels between technicians and their supervisors or team members is vital in overcoming these challenges. Regular communication ensures that everyone involved in the repair process stays informed about any changes or updates related to safety measures or weather conditions.

So while blade repair technicians face various challenges in their line of work, implementing proper safety measures when working at heights and taking precautions against extreme weather conditions can greatly mitigate these risks. By prioritising safety protocols, staying vigilant about changing weather patterns, and maintaining open lines of communication within the team, blade repair technicians can overcome these challenges effectively and carry out their important role with confidence.

The Latest Technologies and Innovations in Blade Repair Techniques for Enhanced Efficiency and Safety

In recent years, there have been significant advancements in blade repair technologies, aimed at improving efficiency and safety in the maintenance of wind turbine blades. These innovations leverage cutting-edge techniques and tools to ensure that repairs are carried out effectively, minimising downtime and maximising energy production.

One notable development is the integration of robotic assistance in blade repairs. Robotic systems equipped with specialised tools can navigate the complex gel-coated surfaces of wind turbine blades, reaching areas that are difficult for human technicians to access. This not only speeds up the repair process but also enhances safety by reducing the need for workers to perform risky tasks at heights.

Additionally, non-destructive testing (NDT) methods have revolutionised blade inspections and diagnostics. NDT techniques specialising in testing such as thermography, ultrasonic testing, and acoustic emission analysis allow for thorough assessments of blade conditions without causing damage. This enables technicians to identify any defects or structural issues early on, facilitating targeted repairs and preventing potential failures.

By combining advanced blade repair technologies with robotic assistance and non-destructive testing methods, the wind energy industry is improving overall efficiency while ensuring safe operations. These innovations not only reduce maintenance costs but also contribute to increased turbine availability and enhanced performance in renewable energy generation.

Career Opportunities and Growth Prospects for Blade Repair Technicians in the Rapidly Expanding Wind Energy Sector

The wind energy sector is experiencing rapid growth, creating numerous career opportunities for individuals interested in pursuing a career as a blade repair technician. As the demand for renewable energy sources continues to rise, so does the need for skilled technicians who can maintain and repair wind turbine blades.

In the wind energy job market outlook, there is a significant demand for blade repair technicians due to the increasing number of wind farms being established globally. These technicians play a crucial role in ensuring the efficient operation of wind turbines by inspecting, repairing, and maintaining turbine blades.

One of the advantages of pursuing a career as a blade repair technician is the potential for career progression. As you gain experience and expertise in this field, you can advance to higher-level positions such as lead technician or supervisor. Additionally, there are opportunities to specialise in specific types of blade repairs, such as category 5 and the most severe damage, or work on larger-scale offshore projects.

The future demand for skilled blade technicians looks promising as more countries commit to transitioning towards clean energy sources. This means that job security and growth prospects are likely to be strong within this industry for many years to come.

Overall, if you have an interest in renewable energy and possess mechanical skills, becoming a blade repair technician can offer promising career opportunities with ample room for growth and advancement.

About Dangle Rope Access

Here at Dangle Rope Access, we provide a variety of comprehensive inspection, access, coatings, and composite (IACC) industrial services. Our services are available to both the private and public sectors.

We offer high-quality proven solutions that will help reduce maintenance costs in both the long and short-term. We are based in Dundee, Scotland and also have offices based in Edinburgh, along with our newly established training centre in Northern Ireland Dangle Academy. Due to our company size and structure, we are able to offer a flexible and versatile approach to the way we run our business and the services that we offer our clients. And, as a leading painting company, we’ve worked on several renewable energy projects in the UK, Europe, and the US.

We work with both on and offshore with wind farm operators, and asset owners. For offshore wind farm maintenance, to onshore building maintenance, we can cover both the East and West coasts.

To find out more about how our team can help you contact us today. Our friendly, professional and helpful team is always on hand to help!

We'd love a share...