Reason Why Industrial Painting is So Important!

What is Industrial Painting?

Industrial painting is an important job that is often overlooked, but can be critical to the success of a asset owing business. Industrial painting contractors are the professionals who provide the expertise and labor to apply industrial coatings and finishes to a variety of surfaces, such as metal, wood, and concrete. These coatings protect the surfaces from corrosion, rust, and other environmental factors, making them last longer and perform better. They also help to reduce the cost of maintenance and repair due to the semi permeable protective properties of the coatings. In this blog post, we will explore the importance of industrial painting, why it is so important, and how industrial painting contractors like Dangle can help you achieve the desired results.

Understanding the Basics of Industrial Painting

Industrial painting is a specialised form of painting that involves the application of paint and coatings to various surfaces, particularly those found in industrial settings. It requires specific knowledge and expertise to ensure that the paint is applied correctly and provides the desired protection and aesthetic appeal demanded in a competitive setting.

One of the most common surfaces that require industrial painting is steel. Steel is widely used in industrial environments due to its strength, durability and relatively low cost. However, it is susceptible to corrosion and rust when exposed to moisture and other environmental factors. To protect steel from these issues, it is important to use the right paint and coatings.

When it comes to painting steel, there are various types of paint and coatings to choose from. Epoxy paint is one of the most commonly used types of paint for steel. It is known for its excellent adhesion and durability, making it ideal for protecting steel beams, structures, and equipment.

Another popular option for protecting against corrosion is zinc rich paint, which is a type of coating that is known for its sacrificial layer properties. This sacrificial layer acts as a shield, safeguarding the underlying surface from the harmful effects of corrosion. Zinc paint works by creating a barrier between the metal substrate and the surrounding environment, limiting moisture, chemicals, and other corrosive agents from reaching the surface and causing damage. This protective layer is highly effective in extending the lifespan of metal structures, equipment, and infrastructure, making zinc paint a widely sought-after solution in various industries. It is commonly used in applications such as automotive, construction, marine, and industrial sectors.

Zinc paint not only provides excellent corrosion resistance but also offers other benefits, including easy application, cost-effectiveness, and versatility. With its ability to adhere to different surfaces, such as steel, aluminum, and galvanized metal, zinc paint can be applied to a wide range of substrates, ensuring comprehensive protection against corrosion. Additionally, this type of paint can be used on both new and existing surfaces, making it a flexible choice for maintenance and repair projects. Moreover, zinc paint is available in various formulations, including primers, topcoats, and single-component systems, offering users a wide selection to meet their specific requirements. Whether it is protecting a steel structure from the harsh outdoor elements or preventing corrosion on industrial machinery, zinc paint is a reliable solution that provides long-lasting protection and peace of mind.

Industrial painting companies specialise in providing industrial paint application services for a wide range of surfaces, including metal, wood, and concrete. These companies have the necessary equipment and expertise to handle large-scale painting projects, such as painting warehouses, factories, and shipyards. They use techniques such as airless industrial painting, which allows for faster and more efficient application of paint on the surface.

If you're considering industrial coating for your business, it is important to properly prepare the surfaces before painting. This includes cleaning, sanding, and priming the surfaces to ensure proper adhesion of the paint. Otherwise it will probably lead to coating failures. It is also important to choose the right type of paint and coatings for your specific needs and understanding paint and coating chemistry is a very complex task and covered in our blog post the basics of corrosion and how to beat it.

The Importance of Industrial Painting

Industrial painting plays a crucial role in the longevity and performance of various surfaces, particularly in industrial settings. Whether it's steel beams, equipment, or structures, applying the right paint and coatings is essential to protect them from corrosion, rust, and other environmental factors. The importance of industrial painting cannot be overstated, as it not only extends the lifespan of these surfaces but also helps businesses save on maintenance and repair costs.

When it comes to protecting steel, industrial painting becomes even more significant. Steel is widely used in industrial environments due to its strength and durability. However, it is highly susceptible to corrosion and rust when exposed to moisture and other elements. That's where the right paint and coatings come into play.

Epoxy paint is one of the best options for steel. It is known for its exceptional adhesion and durability, making it an ideal choice for protecting steel beams, structures, and equipment. This type of paint creates a strong barrier that prevents moisture and other corrosive agents from reaching the metal surface. Additionally, epoxy steel coatings can withstand harsh industrial environments and provide long-lasting protection.

Zinc paint is another popular choice for industrial painting on steel surfaces. It creates a sacrificial layer of protection, which means it corrodes instead of the steel when exposed to environmental factors. This not only prevents rust but also helps to extend the life of the steel structure or equipment.

Industrial painting is not limited to steel alone. It also encompasses other surfaces like wood and concrete. For example, in shipyards, where exposure to water and salt is constant, industrial painting is crucial for protecting ships and maritime structures. By applying the right paint and coatings, shipyard painters can ensure that the vessels are shielded from the harsh marine environment.

Types of Surfaces that Require Industrial Painting

Industrial painting is essential for protecting a variety of surfaces from environmental damage and ensuring their durability. One common surface that requires industrial painting is steel, which is widely used in industrial settings due to its strength, cost-effectiveness, and durability.

Despite its strength, steel is prone to corrosion and rust when exposed to moisture and other damaging elements. That's why it is crucial to choose the right paint and coatings to provide a protective barrier. By selecting the appropriate coating, the steel surface can be effectively shielded from the corrosive effects of moisture and other harmful elements. This not only prolongs the lifespan of the steel but also preserves its structural integrity and improves its performance.

When it comes to painting steel, there are specific types of paint and coatings that are best suited for the job. Epoxy paint is one of the top choices for painting steel beams, structures, and equipment. It is known for its exceptional adhesion and durability, creating a strong barrier that can slow the passage of moisture and corrosive agents from reaching the metal surface. Epoxy paint is highly resistant to chemicals and can withstand harsh industrial environments, providing long-lasting protection for steel.

Another popular choice for industrial painting on steel surfaces is zinc paint. This type of paint creates a sacrificial layer of protection, meaning it corrodes instead of the steel when exposed to environmental factors. Zinc paint not only mitigates rust but also extends the life of the steel structure or equipment. It is particularly effective in marine environments, where exposure to water and salt is constant.

Industrial painting is not limited to steel alone. It also encompasses other surfaces such as wood and concrete. In industries such as shipyards, where exposure to water and salt is constant, industrial painting plays a crucial role in protecting ships and maritime structures. By applying the right paint and coatings, shipyard painters can ensure that vessels are shielded from the harsh marine environments.

Overall, understanding the types of surfaces that require industrial painting is essential for businesses looking to protect their assets and ensure their longevity. Whether it's steel, wood, or concrete, using the right paint and coatings can make all the difference in maintaining the integrity of these surfaces and avoiding costly repairs. So, when considering industrial painting, it's crucial to choose the best paint for the specific surface and seek the expertise of industrial painters or industrial coating specialists near you.

Preparing the Surface for Industrial Painting

Preparing for industrial painting is crucial to ensure that the paint and coatings adhere properly to the surface and provide effective protection.

Whether you're painting steel, wood, or concrete, proper preparation is essential for achieving the desired results.

When it comes to painting steel, the first step is to clean the surface thoroughly. Any dirt, oil, or rust should be removed to ensure proper adhesion of the paint. This can be done through pressure washing or using solvents specifically designed for cleaning metal surfaces.

After cleaning, it is important to inspect the surface for any defects or damage that may need to be addressed before painting. This includes repairing any cracks, holes, or dents in the steel often called imperfections. Filling these imperfections with the appropriate filler or putty will ensure a smooth surface for the paint to adhere to.

Once the surface is clean and repaired, it's time to prime. Priming is an essential step in the painting process, as it helps the paint adhere better to the surface and provides an extra layer of protection. When choosing a primer, make sure it is specifically designed for the type of surface you are painting. For steel, there are primers available that are specifically formulated for metal surfaces and its generally accepted as best practice in the coatings industry if this stage of the industrial painting process is done by brush to ensure the paint product is correctly worked into the surface.

After priming, it's time to allow the paint to correctly dry according to the Technical Data Sheet or Product Data Sheet from the paint manufacturer. When choosing a paint for steel, consider using epoxy paint or zinc paint, as mentioned earlier. These types of paints are highly durable and provide excellent protection against corrosion with often shorter drying cycles which for undercoats are referenced by the overcoating period. It is important to apply the paint evenly and follow the manufacturer's instructions for drying times and re-coating.

In addition to proper surface preparation, it is also important to take safety precautions during the painting process. This includes wearing protective gear such as goggles, gloves, and a respirator to protect yourself from fumes and paint particles. Adequate ventilation is also crucial when working with industrial paints. All safety data can be found on the Material Safety Data Sheet which you can get from the manufacturer of the product.

Best Practices for Industrial Painting

When it comes to industrial painting, following best practices is essential to ensure a successful and long-lasting industrial paint scope of work. Whether you're painting steel, wood, or concrete, these practices will help you achieve the desired results and maximise the protection provided by the paint and coatings.

First and foremost, it is crucial to properly prepare the surface before painting. This includes cleaning, repairing any defects, and applying a suitable primer. For example, when painting steel, it is important to clean the surface thoroughly to remove any dirt, oil, or rust. This can be done through pressure washing usually to a minimum of 2500 psi and/or using specialised solvents compatible with the paint and coating product. Additionally, any cracks, holes, or dents should be repaired before painting to ensure a smooth surface.

Choosing the right paint and coatings is also a key aspect of industrial painting. For steel surfaces, epoxy paint and zinc paint are among the best options as discussed earlier. Epoxy paint provides excellent adhesion and durability, making it ideal for protecting steel structures and equipment. Zinc paint, on the other hand, creates a sacrificial layer of protection and is particularly effective in marine environments.

Proper application of the paint is another important factor. It is essential to apply the paint evenly and follow the manufacturer's instructions for thickness, drying times and re-coating. Using the appropriate tools and techniques, such as airless industrial painting, can help achieve a professional finish.

Safety should never be overlooked when it comes to industrial painting. It is crucial to wear protective gear, such as goggles, gloves, and a respirator, to protect yourself from fumes and paint particles. Adequate ventilation is also necessary to ensure a safe working environment.

DIY vs Hiring a Professional Industrial Painter

When it comes to industrial painting, you may be wondering if you should tackle the job yourself, maybe hire in someone like a handyman who knows a little bit about painting or hire a professional, who you know is going to the more expensive out of the three options you have. While DIY projects can be a great way to save money and take pride in your work, industrial painting is a specialised task that requires specific knowledge and expertise, so the latter will only come to save you expensive mistakes or even complete rework!

So, let's take a closer look at the pros and cons of DIY vs hiring a professional industrial painter.

One of the main advantages of DIY industrial painting is the potential cost savings. By doing the job yourself, you can avoid paying labor costs and potentially reduce material costs. However, it's important to consider the skill and experience required for a successful industrial painting project. Industrial painting is not just about applying paint; it involves proper surface preparation, choosing the right paint and coatings, and using the correct application techniques. Without the necessary expertise, you may end up with a subpar result that fails to provide adequate protection for your surfaces.

Another factor to consider is the time and effort involved in industrial painting. Depending on the size and complexity of the project, industrial painting can be a time-consuming task. By hiring a professional painting and access contractor like Dangle, you can free up your time and focus on other aspects of your business. Professionals like us also have access to specialised equipment and tools that can expedite the painting process and ensure a high-quality finish.

Additionally, professional industrial painters have the knowledge and experience to recommend the best paint and coatings for your specific needs. Whether it's epoxy paint for steel, zinc paint for steel, or other industrial coatings, they can help you make informed decisions to maximise protection and longevity. They also have access to a wider range of industrial paint products and may be able to secure better pricing than you could on your own.

While DIY industrial painting may seem like a tempting option, especially for smaller projects, it's important to weigh the risks and rewards. When it comes to protecting valuable assets like steel structures and equipment, investing in professional industrial painting can provide peace of mind and ensure a long-lasting finish. So, consider the scope and complexity of your project, as well as your own skill level and available time, before deciding whether to DIY or hire a professional industrial painter.

In summary, industrial painting requires specialised knowledge and expertise to ensure a successful and long-lasting result. While DIY projects can save money, the risks of improper surface preparation, incorrect product selection, and inadequate application techniques may outweigh the benefits. Hiring a professional industrial painter not only ensures a high-quality finish but also saves you time and provides access to expert recommendations.

Industrial Painters Near Me

If you're in need of industrial painting services, you may be wondering, "Where can I find industrial painters near me?" Luckily, there are numerous industrial painting contractors available that can help you achieve the results you desire.

When searching for industrial painters, it's important to consider their expertise and experience in the field. Look for contractors who specialize in industrial painting and have a proven track record of successful projects. You can start by asking for recommendations from colleagues or industry professionals who have previously used industrial painting services.

Another useful tool in finding industrial painters near you is the internet. Conduct a quick search using keywords such as "industrial painters" or "industrial coatings near me." This will provide you with a list of local contractors that offer industrial painting services. Take the time to read through their websites and learn more about their services, experience, and client testimonials.

Once you have a list of potential industrial painters, it's important to narrow down your options. Contact each contractor and request a coating consultation or painting estimate. This will allow you to discuss your specific needs and expectations for the project. During the consultation, ask about the types of paint and coatings they recommend for your surfaces. Discuss your budget and timeline to ensure that they can accommodate your requirements.

When evaluating potential industrial painters, don't forget to consider their pricing. While cost shouldn't be the sole determining factor, it's important to find a contractor that offers competitive rates without sacrificing quality. Remember, investing in professional industrial painting can save you money in the long run by extending the life of your surfaces and reducing maintenance and repair costs.

In conclusion, finding industrial painters near you is an important step in achieving the desired results for your industrial painting project. Take the time to research and evaluate different contractors to find the one that best suits your needs. By choosing a reputable and experienced industrial painting contractor, you can ensure that your surfaces are properly protected with high-quality paint and coatings for years to come.

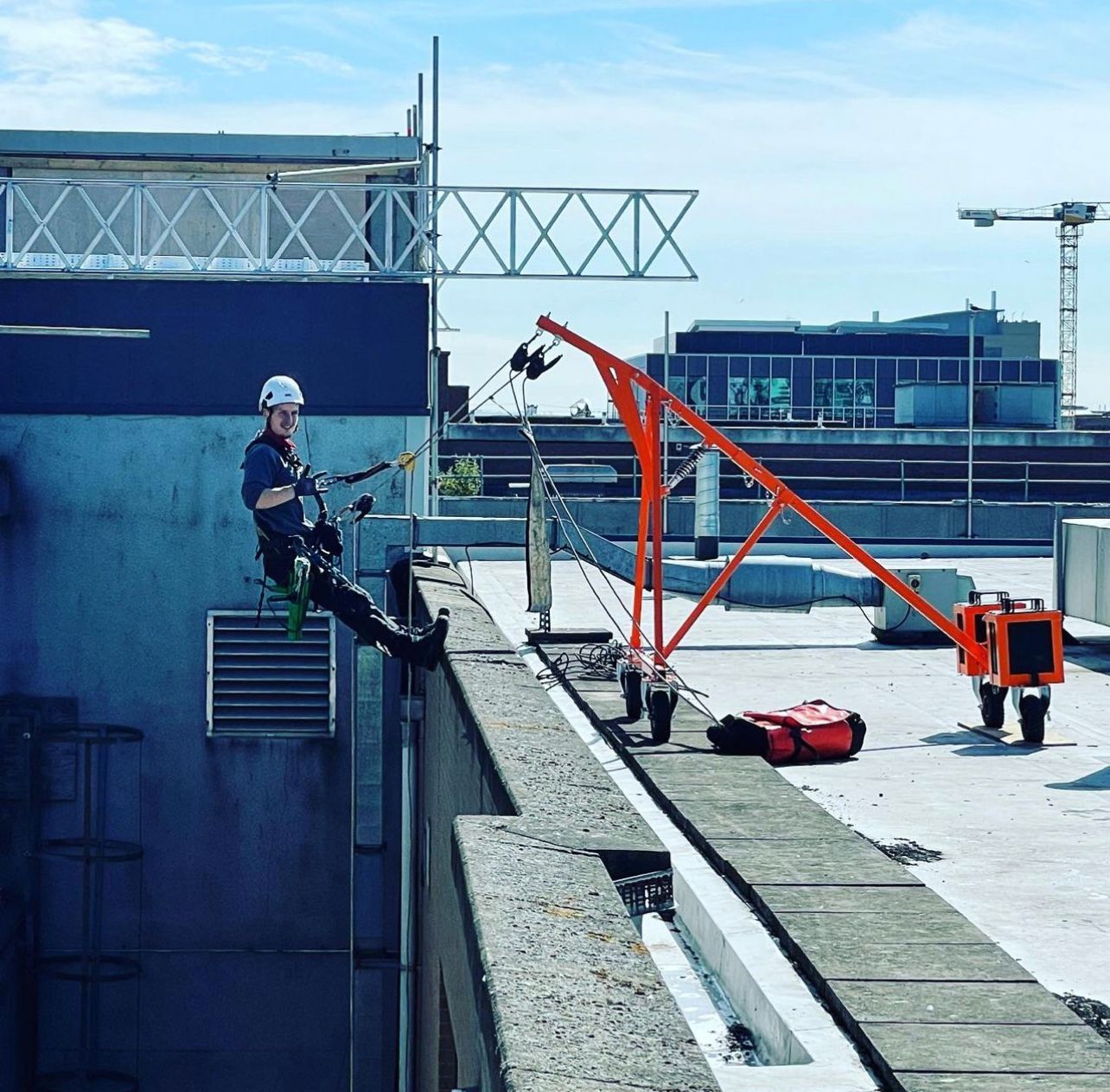

About Dangle Rope Access

Here at Dangle Rope Access, we provide a variety of comprehensive inspection, access, coatings, and composite (IACC) industrial services. Our services are available to both the private and public sectors.

We offer high-quality proven solutions that will help reduce maintenance costs in both the long and short-term. We are based in Dundee, Scotland and also have offices based in Edinburgh, along with our newly established training centre in Northern Ireland Dangle Academy. Due to our company size and structure, we are able to offer a flexible and versatile approach to the way we run our business and the services that we offer our clients. And, as a leading painting company, we’ve worked on several renewable energy projects in the UK, Europe, and the US.

We work with both on and offshore with wind farm operators, and asset owners. For offshore wind farm maintenance, to onshore building maintenance, we can cover both the East and West coasts.

To find out more about how our team can help you contact us today. Our friendly, professional and helpful team is always on hand to help.

We'd love a share...